Audience: Product Developers and R&D Teams

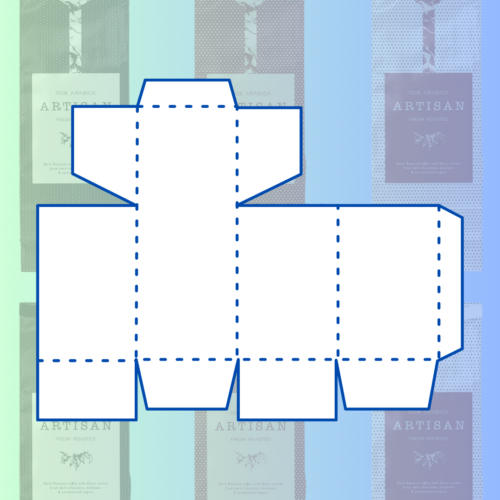

Importance of Dielines in Quoting Co-Packing Projects

One of the most critical factors in providing an accurate co-packing quote is the dieline. Without it, pricing and feasibility assessments become challenging, often leading to delays, cost discrepancies, or unexpected production issues.

Finding the Right Candy Co-Packer: What Brands Need to Know

The candy industry is evolving, with brands looking for efficient, scalable ways to bring their products to market. Whether launching a new line of gummies, chocolates, or hard candies, partnering with a candy co-packer can streamline production while maintaining quality. But how do you find the right co-packer for your brand? And what should you […]

Finding the Right Candy Co-Packer: What Brands Need to Know

The candy industry is evolving, with brands looking for efficient, scalable ways to bring their products to market. Whether launching a new line of gummies, chocolates, or hard candies, partnering with a candy co-packer can streamline production while maintaining quality. But how do you find the right co-packer for your brand? And what should you […]

Co-Packing for Organic and Non-GMO Food Products

Co-packing plays a pivotal role in the food industry, especially for brands focused on organic and non-GMO products. According to the Organic Trade Association, sales of organic food in the U.S. grew by 12.4% in 2020, reaching a record $62 billion, while demand for non-GMO products continues to rise as consumers prioritize transparency and health (Organic Trade Association, 2021).

Co-Packing for Organic and Non-GMO Food Products

Co-packing plays a pivotal role in the food industry, especially for brands focused on organic and non-GMO products. According to the Organic Trade Association, sales of organic food in the U.S. grew by 12.4% in 2020, reaching a record $62 billion, while demand for non-GMO products continues to rise as consumers prioritize transparency and health (Organic Trade Association, 2021).

Private Label Food Packaging: Leverage Co-Packing to Scale Your Brand Faster

Private label food packaging allows companies to differentiate their products on store shelves without the overhead of in-house production.

Private Label Food Packaging: Leverage Co-Packing to Scale Your Brand Faster

Private label food packaging allows companies to differentiate their products on store shelves without the overhead of in-house production.

Press Release: Econo-Pak Announces Major Co-Packing Facility Expansion

Explore how Econo-Pak’s facility expansion enhances our co-packing capabilities. See event photos, watch the highlights video, and learn more!

Press Release: Econo-Pak Announces Major Co-Packing Facility Expansion

Explore how Econo-Pak’s facility expansion enhances our co-packing capabilities. See event photos, watch the highlights video, and learn more!

What are Induction Seals?

Induction seals seals not only protect products but also help maintain their quality and extend shelf life. Let’s examine the benefits that make induction seals an integral part of modern food packaging.