Topic: Co-packing Operations

How Can Offering Multiple Packaging Sizes Improve Sustainability?

When companies look for ways to improve sustainability, packaging is often one of the first places to start. Choosing the right size package does more than just affect the customer experience. It can also significantly reduce excess waste, improve transportation efficiency, and help brands align with long term sustainability goals. Offering a variety of packaging […]

New Hire, Real Talk

https://youtu.be/xtdwsun3eg4 In this episode of the Econo-Pak Contract Food Packaging Podcast, Mike Mee welcomes new Sales and Marketing Coordinator, Olivia Dodsworth. Together they discuss the value of working with a full-service contract food packaging partner, the growing range of packaging formats available at Econo-Pak, and how new marketing tools like newsletters and resource hubs are […]

Why is Flexibility in Packaging Lines Critical in Seasonal Demand?

When seasonal demand hits, brands must adapt quickly. From holiday snacks to limited-edition flavors, product demand can surge overnight. The ability to respond fast without slowing production or compromising quality depends on one key factor: flexibility! Econo-Pak does this right. Meeting Seasonal Spikes Efficiently Seasonal peaks can put enormous pressure on packaging operations. A flexible […]

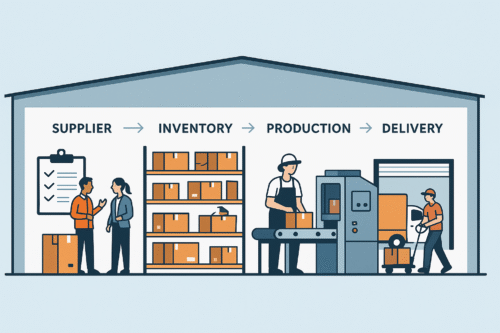

Why Is End to End Procurement Cost Effective?

When brands choose a co-packer, they want more than production capacity. They want reliable supply, faster timelines, and cost control. End to end procurement helps deliver all three by managing every part of the sourcing process from vendor selection to delivery. What Is End to End Procurement? End to end procurement means the co-packer oversees […]

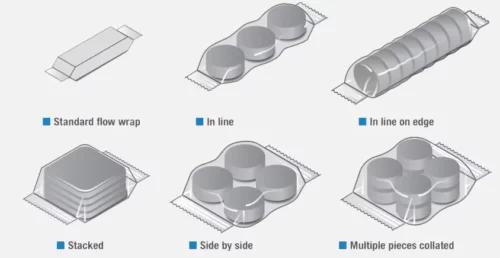

How Does Flow Wrapping Keep Products Fresh and Shelf Ready?

When it comes to food packaging, freshness and presentation matter most. Flow wrapping is one of the most reliable and efficient packaging methods for protecting food products, extending shelf life, and ensuring a clean, consistent look on store shelves. At Econo-Pak, our advanced flow wrapping systems are designed to maintain quality while maximizing efficiency. What […]

How Do You Choose the Right Co-Packer for Your Food Brand?

How to Choose the Right Co-Packer for Your Food Brand Choosing the right co-packer is one of the most important decisions a food company can make. The right partner protects your brand, keeps costs under control, and helps you scale. The wrong one can lead to delays, quality issues, or missed opportunities. Here is what […]

Why is Portion Controlled Packaging Essential for Today’s Consumers?

Meeting today’s consumer expectations Consumers are more conscious than ever about convenience, health, and value. They want products that fit their busy lifestyles, help manage portions, and deliver consistent quality. Portion controlled packaging is one of the most effective ways food brands can address these evolving demands. By offering products in single-serve or pre-measured sizes, […]

What Is the Role of Automation in Achieving Volume Flexibility?

In today’s food industry, demand isn’t always predictable. One week, a brand might need a small run for a seasonal product; the next, they could be scaling up to meet nationwide distribution. That’s where volume flexibility comes in—and automation plays the starring role. At Econo-Pak, automation isn’t just about speed. It’s about building a system […]

Variety Packs: Design, Strategy, and Impact on Shelf Performance

Variety packs are a proven way to attract consumers and boost retail sales. By offering multiple flavors or product types in one package, they provide convenience and choice while increasing a brand’s shelf presence. Econo-Pak creates variety pack solutions that are efficient, reliable, and built to perform. Why Consumers Love Variety Packs Shoppers enjoy variety […]

VFFS (Vertical Form Fill Seal): Choosing Films and Materials for Dry Foods

Vertical Form Fill Seal (VFFS) machines are one of the most efficient solutions for packaging dry foods. From snacks and cereals to powders and mixes, this technology forms, fills, and seals bags in a single streamlined process. To achieve the best results, choosing the right films and materials is essential. At Econo-Pak, we specialize in […]