Audience: Quality Assurance and Food Safety Teams

How Do Packaging Choices Affect Shipping and Storage?

When most brands think about packaging, they often focus on branding, shelf appeal, and product protection. What sometimes gets overlooked is how packaging choices directly affect shipping, warehousing, and overall supply chain efficiency. The size, shape, weight, and durability of your packaging can influence everything from pallet configuration and freight costs to storage capacity and […]

Could the Right Co-Packer Unlock Faster Brand Growth?

Growth is exciting. But it also brings pressure. Orders increase. Retailers call. New opportunities appear fast. Suddenly, the systems that once supported your brand begin to strain. Many emerging brands discover that demand alone does not guarantee success. Sustainable growth depends on operational readiness. This is where the right co-packing partner makes a measurable difference. […]

How Do Co-Packers Ensure Consistent Seasoning at Scale?

Seasoning consistency is one of the most important factors in dry food manufacturing and contract packaging. Today’s consumers expect every bite to taste the same, whether it comes from the first pouch off the packaging line or the final pallet of a high-volume production run. Even small variations in seasoning can lead to flavor imbalance, […]

Is It Time to Move from Bag and Box to Stand Up Pouches?

Choosing the right food packaging format plays a major role in how a brand grows. Packaging impacts efficiency, shelf appeal, shipping costs, and how easily production can scale. Many food brands begin with traditional bag and box packaging, but as demand increases, stand up pouches often become the better long term solution. So how do […]

What Are the Key Benefits of Single Serve Packaging?

Single serve food packaging is growing fast because today’s consumers want convenience, safety, freshness, and clear portion sizes. Brands across snacks, cereals, powders, freeze dried foods, and ready to mix beverages choose single serve packaging to stay competitive in retail, club stores, e commerce, travel, and food service. Below are the key reasons single serve […]

What is the Best Packaging Format?

When brands explore the best packaging format for their products, they often look for packaging that delivers strong shelf appeal, consumer convenience, and operational efficiency. Pre made stand up pouches continue to rank as one of the most effective food packaging solutions because they support branding, protect product quality, and align well with modern manufacturing […]

Does Food Safety Start With Allergen Control?

Allergen control is one of the most important parts of food safety. Every year, food recalls happen because of allergens that were not labeled correctly or came into contact with other products. These mistakes can lead to serious health risks for consumers and major losses for brands. A strong allergen control program is essential for […]

What Business Goals Can a Co Packer Help You Achieve?

Partnering with a co packer is one of the smartest moves a growing food brand can make. Whether your focus is scale, cost savings, or specialty production, the right partner helps you move faster and operate more efficiently. Scale Without the Stress As demand grows, expanding in house can become expensive and time consuming. A […]

What Is the Best Way to Pack Dried and Freeze Dried Snacks?

Dried and freeze dried snacks continue to grow in popularity as brands look for ways to offer convenience, long shelf life, and nutrient dense options. With so many new products entering the category, choosing the right packaging format is one of the most important decisions for both product quality and customer experience. The right pack […]

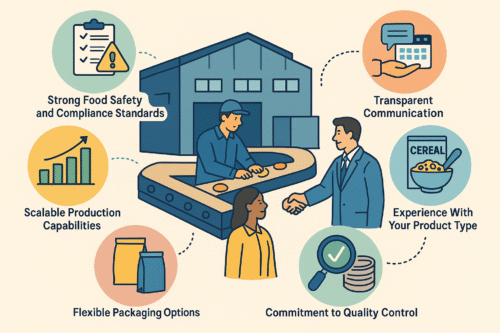

What Are 7 Things Food Brands Should Look For in a Co-Packer?

Choosing the right co-packer is one of the most important decisions a food brand can make. The right partner can help you scale fast, protect product quality, reduce complexity, and strengthen your brand reputation. The wrong partner can slow growth, damage customer trust, and create costly production issues. Here are seven key things to look […]