Could the Right Co-Packer Unlock Faster Brand Growth?

Comments Off on Could the Right Co-Packer Unlock Faster Brand Growth?

Growth is exciting. But it also brings pressure.

Orders increase. Retailers call. New opportunities appear fast. Suddenly, the systems that once supported your brand begin to strain. Many emerging brands discover that demand alone does not guarantee success. Sustainable growth depends on operational readiness.

This is where the right co-packing partner makes a measurable difference.

A strategic partner does more than package your product. They help you move faster, scale smarter, and prepare for what comes next.

So ask yourself: Is your current partner built for growth?

Why Your Co-Packer Has a Direct Impact on How Fast You Scale

Your packaging operation influences nearly every part of your business. From production speed to retailer relationships, the right partner can remove barriers that often slow expansion.

When brands outgrow their packaging capabilities, the warning signs usually appear quickly:

Production timelines start slipping

Large orders feel difficult to support

Manual processes create inefficiencies

Storage becomes limited

Speed to market slows

Growth should create momentum, not operational stress.

The right contract packaging partner helps ensure your infrastructure keeps pace with demand so you can focus on sales, innovation, and brand building.

The Hidden Bottlenecks That Slow Brand Expansion

Many brands assume packaging is simply the final step before shipping. In reality, it is one of the most critical drivers of scalability.

Without the right co-manufacturer, growth can stall due to challenges such as:

Limited production capacity

If your partner cannot handle higher volumes, your ability to expand into new retailers becomes restricted.

Lack of automation

Automated packaging supports consistency, efficiency, and faster output. Manual processes often introduce delays and increase costs over time.

Inflexible packaging formats

As your brand evolves, you may need single-serve packaging, club sizes, or stand-up pouches. A partner without flexibility can limit your expansion strategy.

Operational growing pains

Switching partners during a high-growth phase can disrupt momentum. Choosing the right partner early helps prevent this risk.

Simply put, your co-packer should never be the reason you turn down new business.

What High-Growth Brands Look for in a Co-Packing Partner

Brands preparing for rapid expansion tend to prioritize partners who are built for long-term scale.

Key capabilities often include:

High-volume production

Infrastructure designed to support both current demand and future growth.

Automation investments

Modern equipment that improves speed, accuracy, and efficiency.

Flexible packaging solutions

The ability to support multiple formats as your retail presence expands.

Operational expertise

Teams that understand how to streamline processes and anticipate challenges before they happen.

A partnership mindset

Because growth is rarely linear. You need a partner ready to adapt with you.

The strongest partnerships are proactive, not reactive.

How the Right Partner Helps You Reach the Market Faster

Speed matters more than ever. Retail windows are competitive, and consumer demand shifts quickly.

A reliable contract packaging partner helps accelerate timelines by:

Increasing production efficiency

Reducing changeover delays

Supporting forecast growth

Maintaining consistent quality

Improving supply chain coordination

When operations run smoothly, your brand can confidently pursue larger opportunities.

Faster execution often separates brands that scale from those that stall.

Ready to Unlock Faster Growth?

The question is no longer whether your brand can grow. The real question is whether your co-packing partner is equipped to grow with you.

At Econo-Pak, growth is not something we react to. It is something we help build. Through advanced automation, high-volume production, and flexible packaging solutions, we give brands the operational strength needed to scale with confidence. When opportunity appears, you should be ready to capture it, not scrambling to support it.

If you are looking for a contract packaging partner that is prepared for what comes next, Econo-Pak is ready to help you move faster, operate smarter, and grow stronger.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

How Do Co-Packers Ensure Consistent Seasoning at Scale?

Comments Off on How Do Co-Packers Ensure Consistent Seasoning at Scale?

Seasoning consistency is one of the most important factors in dry food manufacturing and contract packaging. Today’s consumers expect every bite to taste the same, whether it comes from the first pouch off the packaging line or the final pallet of a high-volume production run. Even small variations in seasoning can lead to flavor imbalance, negative customer experiences, and expensive product rework.

For brands preparing to scale, the right co-packer does more than fix problems after they occur. A strategic co-manufacturing partner builds processes that prevent inconsistencies before production even begins.

Why Seasoning Consistency Becomes More Difficult at Scale

As production grows, maintaining uniform flavor across every unit becomes more complex. Higher volumes place greater demands on equipment, ingredient management, and process control.

Key factors that influence seasoning consistency include:

Ingredient flow and measurement accuracy

Blend uniformity

Equipment calibration

Application methods

Production speed

Changeover efficiency

Without strong operational controls, large-scale food production can introduce risks such as uneven coating, seasoning separation, and batch-to-batch flavor variation.

This is where an experienced co-packer creates measurable value.

Built for Consistency From Day One

At Econo-Pak, seasoning consistency is engineered into the production process, not inspected at the finish line.

From raw ingredient handling through automated packaging, every step is designed to support repeatable, scalable results. This proactive approach allows teams to identify potential issues early, reduce production risk, and protect product quality.

For growing brands, this means greater confidence when expanding into new retailers, larger distribution channels, or higher volume programs.

Precise Ingredient Handling Supports Flavor Accuracy

Consistent seasoning starts long before application. Proper ingredient storage, controlled handling, and carefully managed blending processes help maintain uniform seasoning profiles throughout production.

These systems help prevent:

Clumping

Settling

Ingredient separation

Moisture exposure

Inconsistent particle distribution

The result is a stable seasoning blend that delivers reliable flavor from the first run to the millionth unit.

Advanced Equipment Drives Uniform Seasoning Application

Modern co-packing relies on equipment designed for accuracy and efficiency. Automated seasoning systems help ensure controlled distribution and steady product flow across high-speed production lines.

At Econo-Pak, equipment is routinely calibrated, monitored, and maintained to support even coverage across every batch. Continuous oversight allows teams to make real-time adjustments that keep flavor profiles aligned with brand expectations.

This level of precision is especially critical for brands entering rapid growth phases where consistency directly impacts customer loyalty.

Quality Control That Protects Your Brand

Strong quality systems are essential in contract packaging and food manufacturing. Standardized procedures, trained production teams, and in-process inspections help ensure seasoning remains consistent across:

Multiple SKUs

Long production runs

Various packaging formats

Retail and club store requirements

These disciplined controls create repeatability, which is one of the most important advantages a co-packer can offer scaling brands.

Efficient Changeovers Without Sacrificing Consistency

Brands with diverse product lines need a co-manufacturer that can manage flavor transitions smoothly. Poor changeover practices can lead to cross-contact, wasted product, and production delays.

Econo-Pak uses structured changeover protocols and clear documentation to protect flavor integrity while keeping lines moving efficiently. This allows brands to expand their product offerings without increasing operational risk.

The Right Co-Packer Helps You Scale With Confidence

Seasoning consistency should never be a concern when your brand is growing. With the right co-packing partner, large-scale production can deliver dependable, repeatable flavor that keeps customers coming back.

Econo-Pak is built to anticipate challenges, design smarter processes, and support long-term brand success. Through advanced automation, disciplined quality control, and scalable packaging solutions, Econo-Pak helps brands protect product integrity while accelerating growth.

When consistency matters and growth is the goal, the partner behind your production makes all the difference.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

Is It Time to Move from Bag and Box to Stand Up Pouches?

Comments Off on Is It Time to Move from Bag and Box to Stand Up Pouches?

Choosing the right food packaging format plays a major role in how a brand grows. Packaging impacts efficiency, shelf appeal, shipping costs, and how easily production can scale. Many food brands begin with traditional bag and box packaging, but as demand increases, stand up pouches often become the better long term solution.

So how do you know when it is time to move from bag and box packaging to stand up pouches?

What Is Bag and Box Packaging?

Bag and box packaging is commonly used for dry food products such as snacks, baked goods, and powdered foods. These formats can work well for small runs and early stage brands.

Benefits of bag and box packaging include:

Familiar packaging format for consumers

Simple setup for limited production volumes

Lower upfront complexity for new brands

As brands scale, however, bag and box packaging can limit efficiency and increase costs.

Why Stand Up Pouches Are Growing in Popularity

Stand up pouches are one of the most widely used packaging formats in the food industry today. They offer flexibility, efficiency, and strong shelf presence, especially for growing brands.

Key benefits of stand up pouch packaging include:

Improved shelf appeal and brand visibility

Better use of space for storage and shipping

Flexible sizing for single serve and multi serve packaging

Strong protection for dry food products

Compatibility with automated, high volume packaging lines

For brands expanding into grocery, club stores, airlines, and foodservice, stand up pouches often provide a competitive advantage.

Bag and Box vs Stand Up Pouches for Scaling Production

When production volumes increase, packaging efficiency becomes critical. Stand up pouches are designed to run efficiently at higher speeds and larger volumes.

At scale, stand up pouches can help brands:

Increase packaging speed and throughput

Reduce labor requirements

Improve consistency across large production runs

Lower shipping and storage costs

Support multiple SKUs and pack sizes

These advantages make stand up pouch packaging a strong choice for brands preparing for growth.

Signs It Is Time to Switch to Stand Up Pouches

Your brand may be ready to move from bag and box packaging to stand up pouches if:

Production volumes are increasing

Shipping and storage costs are rising

Shelf presence is becoming more important

New products or pack sizes are being added

Expansion into new markets or retail channels is planned

Packaging should support growth, efficiency, and long term success.

How Econo-Pak Supports Stand Up Pouch Packaging

Choosing the right contract food packaging partner is just as important as choosing the right packaging format. Econo-Pak specializes in stand up pouch packaging for dry food brands looking to scale.

With advanced automation, high volume packaging capabilities, and experience across a wide range of dry food products, Econo-Pak helps brands transition from bag and box packaging to stand up pouches with confidence. From optimizing packaging formats to ensuring consistent quality and efficiency, Econo-Pak provides the support brands need to grow.

When your packaging partner understands growth, scaling becomes easier.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

What Are the Key Benefits of Single Serve Packaging?

Comments Off on What Are the Key Benefits of Single Serve Packaging?

Single serve food packaging is growing fast because today’s consumers want convenience, safety, freshness, and clear portion sizes. Brands across snacks, cereals, powders, freeze dried foods, and ready to mix beverages choose single serve packaging to stay competitive in retail, club stores, e commerce, travel, and food service.

Below are the key reasons single serve packaging has become a top solution for modern food brands.

Single Serve Packaging Keeps Food Safe

Food safety is the most important factor in every product. Single serve packaging keeps food protected from oxygen, moisture, and contamination. Each portion is sealed immediately, which improves shelf stability and reduces food safety risks.

This is especially valuable for allergen heavy categories like cereals, oatmeal cups, dried fruit, nuts, granola, powders, and freeze dried snacks. With the right co packing partner, brands gain strict quality control, consistent product protection, and reliable certification support.

Portion Control Helps Consumers and Reduces Waste

Portion control is one of the top reasons customers choose single serve products. Each unit gives shoppers the perfect amount. This helps with healthy eating, calorie tracking, and better nutrition habits.

Brands benefit from portion control because it lowers product waste and keeps serving sizes accurate. Consistency also helps with pricing, nutrition labeling, and customer satisfaction. Single serve packaging makes the user experience simple and predictable.

Economies of Scale Improve Production Costs

Single serve packaging can create strong cost savings when produced at scale. High speed filling lines, automated sealing, and efficient changeovers help brands lower labor costs and improve production output.

By standardizing unit sizes, brands gain better forecasting and easier inventory management. This reduces overproduction and supports smoother supply chain planning. When produced by a high volume co packer, single serve units often deliver stronger margins for retail and food service programs.

Single Serve Packaging Increases Product Variety

Consumers love variety. Single serve packaging allows brands to offer multi flavor packs, seasonal collections, sampler kits, and grab and go formats. Variety packs help customers try new flavors without a large commitment, which increases trial rates and repeat purchases.

Retailers also prefer products with variety because they improve shelf appeal and give shoppers more options. This leads to stronger category performance and higher basket sizes.

Why Econo Pak Has the Best Single Serve Packaging Solution

Econo Pak is a leader in single serve food packaging with high speed lines, advanced equipment, and a large scale facility built for efficiency and accuracy. We support a wide range of single serve formats such as pillow pouches, cups, bag in box, flow wrap, and the list continues.

Econo Pak focuses on quality and safety. Our facility is FDA registered, gluten free certified, kosher certified, and Sedex approved. We follow a strict allergen control program that supports safe and consistent production for major allergens.

With more than 200 production lines, quick changeovers, expert onboarding, and full project support, Econo-Pak helps brands grow fast. We deliver large scale single serve packaging for snacks, cereals, powders, freeze dried products, and many other food categories.

If your brand is ready to expand into single serve packaging, the Econo Pak team has the technology, certifications, and experience to bring your product to market with confidence.

What is the Best Packaging Format?

Comments Off on What is the Best Packaging Format?

When brands explore the best packaging format for their products, they often look for packaging that delivers strong shelf appeal, consumer convenience, and operational efficiency. Pre made stand up pouches continue to rank as one of the most effective food packaging solutions because they support branding, protect product quality, and align well with modern manufacturing and logistics needs. This format is widely used across snacks, granola, cereals, candies, seasoning blends, and many dry food categories, making it a trusted option for brands that want scalable, high performance packaging.

Pre made stand up pouches also pair well with contract packaging and co packing operations because they support faster changeovers, flexible SKU programs, and strong production efficiencies.

Benefits of Pre Made Stand Up Pouch Packaging

Pre made pouches provide a balance of performance, storage efficiency, and visual impact. Brands value this format because it supports both retail presentation and scalable food packaging operations.

Key advantages include:

Strong shelf visibility and billboard-style branding

Lightweight packaging that reduces shipping weight

Efficient case packing and palletization

Resealable features for freshness and convenience

Flexible sizing across multiple SKUs and product lines

These benefits make stand up pouch packaging a powerful option for both established brands and growing consumer packaged goods companies.

Why Econo Pak is a Strong Co Packing Partner for Stand Up Pouches

Econo Pak has extensive experience as a contract packaging company specializing in pre made stand up pouch filling and sealing. Our processes are designed for speed, consistency, and large-scale production.

Our pouch packaging capabilities include:

High efficiency filling and sealing lines

Fast changeovers across multiple SKUs

Strong fill accuracy and seal integrity

Production scalability for regional and national programs

We support a wide range of dry food products, including:

Snacks and trail mixes

Cereals and granola

Oatmeal cups and breakfast blends

Candy and confectionery items

Seasonings and dry ingredient blends

Our allergen control program and food safety systems help protect product integrity throughout the packaging process.

Certifications That Support Customer and Retail Requirements

Econo Pak maintains key quality certifications that strengthen trust and support retailer approval. These include:

FDA registration

Gluten free certification (where applicable)

Kosher certification

Sedex certification

Formal allergen control programs

These programs help brands enter new markets and expand product distribution with confidence.

Choose Econo Pak for Pre Made Stand Up Pouch Packaging

Pre made stand up pouches are one of the most versatile and efficient packaging formats in modern food packaging. With strong branding opportunities and supply chain benefits, they continue to be a top choice for many consumer packaged goods brands.

Econo Pak is a reliable co packing partner for stand up pouch packaging, offering production efficiency, quality control, and scalable contract packaging solutions.

Does Food Safety Start With Allergen Control?

Comments Off on Does Food Safety Start With Allergen Control?

Allergen control is one of the most important parts of food safety. Every year, food recalls happen because of allergens that were not labeled correctly or came into contact with other products. These mistakes can lead to serious health risks for consumers and major losses for brands.

A strong allergen control program is essential for any food manufacturer or co-packer. It keeps products safe, protects consumers, and builds trust with retailers and customers. For brands that rely on a co-packing partner, allergen control is one of the top factors to consider.

Why Allergen Management Matters in Food Safety

The FDA identifies nine major food allergens: milk, eggs, fish, shellfish, tree nuts, peanuts, wheat, soy, and sesame. Even small amounts can trigger allergic reactions. This is why every step in food manufacturing must be carefully managed, from ingredient handling to final packaging.

Most allergen-related recalls are preventable. They often occur because of labeling mistakes, cross contact between ingredients, or incomplete cleaning between runs. By following a detailed allergen control program, food brands can avoid these problems and protect their consumers.

What an Allergen Control Program Includes

A successful allergen control program focuses on prevention and consistency. It covers everything from ingredient tracking to staff training. Key parts include:

Ingredient tracking: Every ingredient is labeled, stored correctly, and documented from receiving to packaging.

Segregation: Allergen and non-allergen products are kept separate during storage and production.

Sanitation and cleaning: Equipment is cleaned and tested before switching from one product to another.

Label accuracy: Each package label must match the formula and ingredients inside.

Employee training: Staff are trained to handle ingredients properly and follow allergen safety procedures.

When these steps are followed carefully, brands reduce risk, improve safety, and stay compliant with food regulations.

The Role of Co-Packers in Allergen Safety

Many brands rely on co-packers to produce and package their food products. A trusted co-packing partner becomes an extension of the brand’s food safety program. Because allergens are one of the biggest risks in food manufacturing, co-packers must have strong systems in place to manage them.

An experienced co-packer will follow verified cleaning processes, use ingredient tracking software, and perform label checks throughout production. They should also hold certifications like SQF and FDA registration, which show that their allergen control program meets the highest standards.

Econo-Pak’s Approach to Allergen Control

Econo-Pak understands that allergen management protects both brands and consumers. The company’s allergen control program is built around accuracy, traceability, and prevention. Every step is designed to keep allergens contained and ensure every product is safe before it leaves the facility.

Key parts of Econo-Pak’s allergen management include:

Dedicated allergen and non-allergen rooms and lines

Complete ingredient traceability from receiving through final packaging

Verified sanitation procedures between production runs

Multiple label checks before each shipment

Ongoing employee training on allergen awareness and safety protocols

Econo-Pak’s team works with products that range from allergen-sensitive items to gluten free foods. Each project is handled with customized procedures that match the specific allergen risks involved.

Why Brands Should Care About Allergen Control

Strong allergen management helps brands protect customers and prevent recalls. It also strengthens relationships with retailers who demand proof of safe production. For many consumers, food safety and allergen awareness are deciding factors when choosing what to buy.

When a brand partners with a co-packer that prioritizes allergen safety, it gains confidence in every shipment. Safety becomes a competitive advantage rather than a challenge.

Work with a Trusted Co-Packing Partner

Econo-Pak helps food brands manage allergens safely and efficiently. Our facility, training programs, and documentation systems are built around compliance and quality. If your product requires allergen handling or gluten free production, our team can help you build a program that fits your needs.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

What Business Goals Can a Co Packer Help You Achieve?

Comments Off on What Business Goals Can a Co Packer Help You Achieve?

Partnering with a co packer is one of the smartest moves a growing food brand can make. Whether your focus is scale, cost savings, or specialty production, the right partner helps you move faster and operate more efficiently.

Scale Without the Stress

As demand grows, expanding in house can become expensive and time consuming. A co packer gives you immediate access to production lines, trained teams, and reliable capacity. This keeps your brand flexible and ready for growth without large investments.

Reduce Costs and Improve Efficiency

A co packer lowers operational costs by handling equipment, labor, maintenance, and facility needs. This creates a more efficient production environment and frees up resources for marketing, product development, and new opportunities. Here at Econo-Pak we offer a fixed cost solution.

Support Specialty and Complex Production

Some products require expertise, certifications, or equipment that can be challenging to build internally. A strong co packer brings experience with specialty formats, strict food safety programs, and complex production needs that protect your brand. In addition, we invest in you. We invest in new machinery for your project without asking for any Cap x.

Speed Up Your Timeline

Launching new SKUs and entering new channels requires speed. A co packer shortens timelines with ready to run lines, fast changeovers, and smooth workflows that help you reach shelves sooner. Because all of our machinery is high speed and automated, we specialize in high volume projects.

Strengthen Quality

A reliable co packer maintains consistent quality checks and food safety controls, helping protect your brand reputation with every run. Econo-Pak is an SQF Level 3, FDA-approved, gluten-free certified co-packing and co-manufacturing facility.

The Bottom Line

If your goals include scaling, saving, or producing specialty products, a co packing partner is the key. Econo Pak delivers the speed, expertise, and reliability your brand needs to grow with confidence.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

What Is the Best Way to Pack Dried and Freeze Dried Snacks?

Comments Off on What Is the Best Way to Pack Dried and Freeze Dried Snacks?

Dried and freeze dried snacks continue to grow in popularity as brands look for ways to offer convenience, long shelf life, and nutrient dense options. With so many new products entering the category, choosing the right packaging format is one of the most important decisions for both product quality and customer experience. The right pack keeps moisture out, protects delicate textures, and helps your brand stand out.

Below are the top packaging formats that work best for dried and freeze dried snacks and why each one matters.

Stand Up Pouches

Stand up pouches remain one of the most popular options for dried and freeze dried products. They are lightweight, flexible, and offer strong barrier protection against oxygen and moisture. Their upright shape creates space for bold branding and easy shelf display. Resealable closures also help maintain freshness once opened, which is ideal for snacks that are eaten over time.

Pillow Pouches

Pillow pouches are a great choice for single serve snacks and portion controlled packs. They offer strong protection while keeping packaging costs efficient. Because pillow pouches use minimal materials, they support sustainability goals and are perfect for grab and go items like fruit crisps or dehydrated veggie chips.

Flow Wrap

Flow wrap is a strong choice for dried snacks that need speed, efficiency, and tight sealing. This format creates a snug film around the product and offers a clean, uniform appearance. Flow wrap is ideal for individually wrapped fruit bars, clusters, or shaped snacks that need consistent protection during transport and display.

Bag in Box Formats

For large quantity snacks or food service applications, bag in box formats offer durability, long shelf life, and easy dispensing. They protect product quality during transport and are a strong fit for brands that serve both retail and wholesale customers.

Why Packaging Choice Matters

Dried and freeze dried snacks are sensitive to moisture, light, and oxygen. Selecting the wrong format can lead to texture loss, clumping, or reduced flavor. The best packaging not only preserves quality but also influences customer satisfaction, brand trust, and supply chain efficiency.

Econo Pak Is Your Packaging Solution

From flexible pouches to flow wrap to specialty formats, Econo Pak has the capabilities to pack dried and freeze dried snacks with precision, consistency, and food safety in mind. Econo Pak has and is the solution.

What Are 7 Things Food Brands Should Look For in a Co-Packer?

Comments Off on What Are 7 Things Food Brands Should Look For in a Co-Packer?

Choosing the right co-packer is one of the most important decisions a food brand can make. The right partner can help you scale fast, protect product quality, reduce complexity, and strengthen your brand reputation. The wrong partner can slow growth, damage customer trust, and create costly production issues.

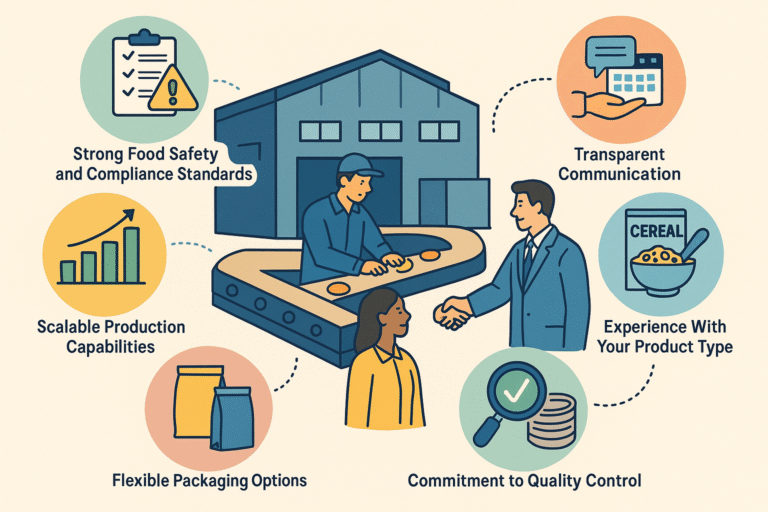

Here are seven key things to look for when choosing a co-packing partner!

1. Strong Food Safety and Compliance Standards

Your co-packer should hold industry-recognized certifications and follow strict food safety programs. Look for certifications such as FDA registration, gluten-free certification, organic handling, SQF or similar quality programs, and ethical sourcing certifications like Sedex. These credentials protect both your product and your brand’s reputation.

2. Scalable Production Capabilities

A co-packer should have the ability to support your brand now and as it grows. That includes multiple production lines, flexible batch sizes, and the ability to scale quickly without compromising quality or lead times. This is what we specialize in, here at Econo-Pak!

3. Flexible Packaging Options

Today’s food brands need packaging variety. Your co-packer should be able to fill and seal a wide range of packaging formats such as pillow pouches, single serve packs, stand up pouches, cups, cartons, and multi-pack configurations. The more capabilities under one roof, the fewer vendors you have to manage.

4. Transparent Communication

Clear timelines, accurate forecasting, and proactive updates are all signs of a reliable co-packing partner. You should always know your production status and have access to real people who can answer questions quickly. At Econo-Pak, we offer a dedicated customer service person for your convenience and easy access to a real person!

5. Commitment to Quality Control

Look for in-house quality checks at every stage of production, from raw ingredient receipt to final quality assurance. Consistency matters, especially when your product ends up on shelves at national retailers.

6. Experience With Your Product Type

Snacks, dry mixes, powders, granola, cereals, functional foods, and shelf-stable products all require different handling and equipment. A co-packer experienced in your exact category will already understand the challenges, compliance needs, and ideal production flow.

7. A True Partnership Mindset

The best co-packers act like an extension of your team. They care about your brand success, not just the production run. Look for partners who offer guidance on packaging design, efficiency improvements, ingredient sourcing, and sustainability options.

Why This Matters to Econo-Pak

The co-packer you choose is a direct extension of your brand. When you partner with Econo-Pak, you are choosing a team with more than 40 years of food packaging experience, 500,000 square feet of production space, and a proven track record of helping food brands scale with confidence.

Econo-Pak offers high-speed production lines, strict food safety certifications, and a wide range of package formats under one roof, which means fewer vendors, faster turnaround times, and more control over product quality. Our priority is protecting your brand reputation while giving you the flexibility to grow, launch new SKUs, and meet retailer demands without disruption.

With Econo-Pak, you are not just buying a packaging service. You are gaining a long-term partner who is invested in your success, just as much as you are.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

How Can Offering Multiple Packaging Sizes Improve Sustainability?

Comments Off on How Can Offering Multiple Packaging Sizes Improve Sustainability?

When companies look for ways to improve sustainability, packaging is often one of the first places to start. Choosing the right size package does more than just affect the customer experience. It can also significantly reduce excess waste, improve transportation efficiency, and help brands align with long term sustainability goals.

Offering a variety of packaging sizes gives brands more flexibility in how products are shipped, stored, and consumed. This flexibility leads to measurable environmental benefits.

1. Less Material Waste

When products have packaging that fits their volume or weight more precisely, there is less unused space. That means less cardboard, plastic, film, or filler materials are needed. By matching packaging size to product size, brands can cut down on material usage and reduce overall waste generation.

2. Reduced Transportation Emissions

Right-sized packaging improves pallet and truck utilization. Smaller or properly sized packages allow more units to fit in each load. This helps companies ship more product using fewer trips. Fewer trips mean lower fuel consumption and reduced carbon emissions throughout the supply chain.

3. Lower Energy Usage in Production

Packaging materials require energy to produce. When less material is used per unit, total energy demand decreases. Even small reductions in packaging footprint can create meaningful energy savings when applied across high-volume production.

4. Better Alignment With Retail and Consumer Needs

Variety in packaging size also prevents over-purchasing and waste at the consumer level. For example, family-size options might serve high-volume buyers, while single-serve formats can reduce food waste for individuals. When customers can choose the size that fits their needs, waste is minimized at the end of the product lifecycle.

5. Easier Compliance With Sustainability Targets

Many retailers and manufacturers have set specific sustainability KPIs related to packaging weight, recyclability, and landfill diversion. Packaging size variety helps meet these goals by providing more efficient options without compromising product protection or shelf appeal.

How Co-Packers Like Econo-Pak Support These Sustainability Outcomes

Working with an experienced co-packer makes it easier for brands to access a wide range of packaging formats without building new internal infrastructure. Econo-Pak’s equipment flexibility allows brands to right-size their packaging based on volume, distribution plans, and sustainability priorities.

From lightweight single-serve film to large volume cartons, Econo-Pak helps companies choose formats that reduce waste, improve transportation efficiency, and support eco-friendly initiatives.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.