Why Food Brands Use Different Oils to Season Their Products

Leave a CommentThe type of oil used to season a product can have just as much impact as the seasoning blend itself. While traditional oils like canola, soybean, and palm have long been the industry standard, more brands are now turning to alternative oils—like avocado oil—to meet evolving consumer preferences.

Whether you’re creating indulgent snacks or aiming for a better-for-you product line, the choice of oil plays a central role in product development, flavor, shelf life, and market appeal.

The shift toward better-for-you oils

Over the past year, demand for healthier oils has grown significantly. As consumers scrutinize ingredient lists and seek out snacks with clean labels, the oil used for seasoning has become a focal point. Avocado oil, in particular, is gaining popularity for its perceived health benefits, such as a high smoke point, heart-healthy monounsaturated fats, and minimal processing.

This shift isn’t limited to niche markets. Large CPG brands and challenger brands alike are reformulating SKUs to replace conventional oils with options like avocado, sunflower, or olive oil. These better-for-you oils often help position snacks as natural, premium, or clean-label—making them more attractive in health food stores, wellness-focused online shops, and club stores like Costco that feature product callouts on front-of-pack labeling.

In this way, oil selection becomes a marketing decision as much as a formulation one.

Oil isn’t just a carrier—it’s a key flavor enhancer

Oil serves a dual role in snack seasoning. Not only does it help seasoning stick to the product surface (whether it’s chips, crackers, or pretzels), but it also contributes to the mouthfeel and taste. Different oils offer distinct sensory experiences

Avocado oil adds a light, buttery flavor and supports a health-forward product positioning.

Sunflower oil is clean and neutral, letting bold seasonings like barbecue or dill pickle shine through.

Olive oil adds a fruity, savory note and works well with Mediterranean-style or gourmet snack flavors.

Oils also play a critical role in how seasoning adheres to the product. Without the right oil-to-seasoning ratio and application technique, seasoning can fall off in the bag, leading to an uneven eating experience and lower perceived quality. That’s why it’s important for food brands to work with a co-packer who understands the functional differences between oil types.

Tailoring oil choice to your product goals

Different snacks require different oil characteristics, depending on the end goal:

Flavor-first products may benefit from oils that enhance or complement bold seasonings.

Health-conscious SKUs often prioritize oils with a better fatty acid profile, lower processing, or non-GMO sourcing.

Shelf-stable items require oils that resist oxidation to maintain freshness and appearance over time.

Cost-sensitive SKUs may stick with traditional oils but explore blends or minimal application to control spend.

Some brands even offer oil-specific product lines—like “avocado oil chips” versus “classic kettle chips”—to cater to multiple audiences and price points. The versatility of oil application allows you to segment your offering based on customer needs and retail channel.

Sustainability and sourcing: a growing concern

Consumers today are more aware of not just what ingredients go into their snacks, but how those ingredients are sourced. Conventional oils like palm and soybean are often associated with deforestation, heavy pesticide use, or GMO production. While some brands still use these oils due to cost-effectiveness, others are switching to more sustainable alternatives to align with ESG goals.

Better-for-you oils such as organic sunflower, high-oleic safflower, and avocado oil are now being marketed as “sustainably sourced,” “non-GMO,” or “cold-pressed.” These claims resonate with buyers who are looking to make environmentally conscious choices.

Working with a co-packer who understands the nuances of sourcing and labeling oils appropriately ensures your product can carry those sustainability claims without risk.

The co-packing advantage: scaling with specialty oils

Applying oil to snacks at scale may sound simple, but it’s a precise operation—especially when working with premium or sensitive oils like avocado oil. These oils may require specific temperature controls, handling procedures, or regulatory documentation to preserve their quality and avoid degradation.

At Econo-Pak, we’re equipped to handle both conventional and specialty oils in high-volume production runs. Our dedicated seasoning lines are designed to:

Evenly apply oil and seasoning to a wide variety of dry food formats

Maintain product integrity and texture throughout the process

Prevent flavor transfer between products with rigorous cleaning procedures

Meet food safety and quality assurance standards with full traceability

We routinely season products such as chips, pretzels, puffed snacks, crackers, and rice-based snacks using oil-and-dry-blend methods. Our team can help test oil types, optimize run speeds, and recommend seasoning approaches that improve product adhesion and consistency.

Whether you’re looking to reformulate an existing product or launch a new line featuring avocado oil or other health-conscious ingredients, we offer the technical expertise and scalable capacity to help you bring it to market quickly and efficiently.

Explore our full seasoning capabilities to learn how we can support your next product run.

Why seasoning flexibility matters in a changing market

The snack industry is evolving rapidly. Retailers are asking for cleaner labels. Shoppers are reading the backs of packages. And brands are under pressure to differentiate themselves in crowded categories.

In this environment, flexibility matters. Brands need a co-packer who can:

Adjust to changing oil preferences and regulatory requirements

Scale production up or down without compromising consistency

Provide insights into seasoning trends and consumer expectations

Collaborate on pilot runs and R&D for emerging oil types

That’s where Econo-Pak stands out. We work with food brands that need more than just a production line—we act as a true partner in product development, packaging, and scaling.

Oil choice is brand choice

The oil you choose for seasoning your snacks is more than a technical detail—it’s a strategic brand decision. As consumer demand continues to grow for better-for-you products, oils like avocado oil are becoming essential to standing out on the shelf and meeting modern expectations.

At Econo-Pak, we’re proud to help brands bring those products to life. From sourcing and seasoning to packaging and scaling, our team is here to support your growth—whether you’re entering a new channel or expanding an existing line.

Explore our contract food manufacturing services to see how we can season your snacks for success.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

Red Flag: When your co-packer asks you to pay for their equipment

Leave a CommentIf your co-packer needs you to foot the bill for their machinery, that’s not a partner—it’s a red flag.

When you’re scaling a food product, working with the right co-packer can unlock growth, simplify operations, and help you break into major markets. But not all co-packers operate the same way. One of the biggest warning signs? Being asked to fund equipment just to get started.

Whether they frame it as “customization” or “shared investment,” this approach often shifts long-term risk onto your shoulders. And that can slow your momentum, drain your budget, and leave you stuck with a setup that only works for one product.

Why this is a red flag

Co-packing is supposed to make production easier—not more expensive. If a facility can’t run your format without a large upfront capital investment from you, it’s worth asking why:

Are they overpromising what they can do?

Are they financially stable?

Will you be tied to one piece of equipment that can’t scale?

In many cases, the equipment you help pay for isn’t even yours. You’re left funding a buildout that may not serve you long-term, especially if your volumes change or your product line evolves.

What a true co-packing partner looks like

At Econo-Pak, we believe a co-packing relationship should feel like an extension of your operations—not a rental agreement.

That’s why we don’t ask clients to front capital for equipment. Instead, we invest in developing efficient, scalable production lines that meet your specific packaging and throughput needs. If automation is needed, we work with our network of equipment partners to find solutions that fit your product—and we absorb that investment.

It’s part of our fixed-cost pricing model, designed to help you scale with confidence and budget predictably.

Questions to ask when evaluating a co-packer:

Do you require brands to pay for machinery or tooling?

What formats can you run today—and what would require modification?

Who owns the equipment once it’s installed?

If my product mix changes, how flexible is your setup?

The right partner is already built to grow with you

Choosing a co-packer is one of the most important decisions a food brand can make. Don’t let sunk costs and shared CAPEX commitments tie you to the wrong one.

Look for a partner that’s invested in your product from day one—without asking you to fund the infrastructure yourself.

Econo-Pak can help you scale with our:

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

Food Allergen Management in Co-Packing Operations

Leave a CommentManaging food allergens is a critical component of every successful co-packing operation. With the growing demand for allergen-free and clean-label products, food brands rely on their contract manufacturers to uphold strict allergen management protocols that protect consumers and maintain brand integrity.

Why allergen management matters in co-packing operations

Cross-contact risks are heightened in large-scale co-packing facilities where a variety of food products—many with common allergens—are processed and packaged on shared lines. Without rigorous allergen controls in place, even trace amounts of an allergen can trigger severe reactions in sensitive individuals, leading to costly recalls and reputational damage.

Food brands looking to expand into new markets must prioritize working with a co-packer experienced in allergen management to meet regulatory requirements and maintain customer trust.

Best practices for allergen management in co-packing facilities

Effective allergen management in co-packing operations starts with detailed planning and oversight throughout every stage of production. Key practices include:

1. Allergen identification and segregation

Co-packers must maintain an updated allergen list and clearly identify all raw materials containing major allergens such as peanuts, tree nuts, dairy, soy, wheat, eggs, fish, and shellfish. Proper storage and physical separation help prevent cross-contact.

2. Production scheduling and line changeover procedures

Strategic scheduling ensures that allergen-containing products are run separately or after allergen-free items when possible. Thorough cleaning and validated changeover protocols are essential to minimize allergen residue between production runs.

3. Dedicated allergen management training

Every employee involved in production, quality assurance, and sanitation receives ongoing allergen training. This reinforces the importance of handling allergenic materials carefully and following established procedures.

4. Label accuracy and verification

Accurate labeling is critical to allergen management. Co-packers must verify that the correct allergen statements appear on every finished package and that ingredient changes triggering allergen updates are communicated promptly.

5. Continuous monitoring and documentation

Routine inspections, allergen swabbing, and third-party audits help maintain allergen control standards. Co-packers should document every step of their allergen management program to provide traceability and demonstrate compliance.

Choosing a co-packer with strong allergen controls

Not every co-packing facility is equipped to handle products with complex allergen requirements. Food brands should seek a partner with:

- Comprehensive allergen management programs

- Third-party food safety certifications

- Dedicated quality assurance teams

- Experience handling products with and without allergens

At Econo-Pak, allergen management is a cornerstone of our co-packing operations. Our team works closely with clients to protect their brand and ensure the safe production of allergen-sensitive products. We help clients navigate allergen requirements, from product intake through final packaging, with processes designed to reduce risk at every step.

How effective allergen management protects your brand

As the demand for transparency and allergen-friendly products continues to grow, food brands need a trusted co-packing partner with proven allergen management expertise. Investing in the right co-packer protects your customers, prevents costly recalls, and positions your brand for success in highly competitive markets.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

Retail Co-Packing 101: What Food Brands Need to Know to Succeed in Retail

Comments Off on Retail Co-Packing 101: What Food Brands Need to Know to Succeed in RetailEntering the retail space for the first time can be a daunting task. The complexities of retail packaging, co-packing services, and maintaining quality standards can be overwhelming.

This is where retail co-packers come into play. Co-packers offer a range of services, from packaging design to production and logistics. They help businesses maintain efficiency and affordability, crucial factors for any company entering retail.

But understanding the nuances of co-packing and co-manufacturing processes is not always straightforward. It requires a deep dive into the industry’s intricacies and a clear understanding of your product’s specific needs.

This article aims to guide packaging managers, CPG start-up CEOs, and contract manufacturing managers through these complexities. It provides a comprehensive understanding of retail packaging strategies, co-packing services, and custom retail packaging.

We will explore the role of retail co-packers, the benefits they offer, and how to choose the right one for your needs. We will also delve into the importance of maintaining quality, efficiency, and affordability in your retail packaging strategy.

So, whether you’re a seasoned professional or a newcomer to the industry, this guide will provide valuable insights to help you navigate the world of retail co-packing. Let’s embark on this journey together.

Table of Contents

Understanding Retail Co-Packers and Their Role

A retail co-packer serves as a bridge between production and retail shelves. Their expertise lies in packaging products efficiently while adhering to industry standards. Co-packers help businesses convert raw materials into retail-ready packages, streamlining the journey from factory to customer.

Key roles of retail co-packers include:

- Ensuring product quality and consistency

- Offering custom retail packaging solutions

- Managing logistics and supply chain efficiencies

Retail co-packers not only package products but also play a vital role in strategizing packaging. They consider market demands and consumer trends, ensuring your product stands out in the retail market.

Moreover, retail co-packers are instrumental for businesses lacking in-house packaging capabilities. Their services allow companies to focus on their core competencies without worrying about packaging logistics. This division of labor results in increased efficiency across the board.

In selecting a co-packer, businesses should consider factors such as scalability, cost efficiency, and alignment with brand values. A good co-packer can make a significant difference in successfully entering the retail market. They not only fulfill packaging needs but also enhance brand perception.

Defining a Retail Co-Packer

A retail co-packer is a specialized packaging partner for retail companies. They focus on transforming bulk products into consumer-ready packages. Their role is pivotal in achieving efficient, scalable operations for companies entering retail.

Unlike traditional manufacturers, co-packers do not alter the product itself. Instead, they provide custom retail packaging solutions that align with business branding. This service is valuable for businesses looking to create a strong market presence without investing heavily in packaging infrastructure.

Retail co-packers bring expertise in packaging design, production, and material selection. They work closely with businesses to ensure packaging meets both practical and aesthetic needs. By collaborating with a co-packer, businesses access this expertise, enhancing their position in the retail landscape.

The Difference Between Co-Packing and Co-Manufacturing

Co-packing and co-manufacturing serve distinct yet complementary roles in supply chains. Co-packing focuses on packaging products, while co-manufacturing involves the actual product creation. Understanding these differences is essential for businesses looking to enter retail effectively.

Co-manufacturers handle the production of goods, including ingredient sourcing and processing. They deliver finished products ready for final packaging. Meanwhile, co-packers take these finished products and focus on packaging them in a way that appeals to consumers and retailers.

Retail co-packers provide specialized packaging services, ensuring the end product is market-ready. They focus on packaging aesthetics, functionality, and compliance. Co-manufacturers, however, emphasize producing quality goods that meet formulation specifications. Each plays a critical role in the seamless flow from production to retail.

The Importance of Co-Packers for New Retail Entrants

For businesses venturing into retail, co-packers provide invaluable support. They offer an existing infrastructure tailored to mass production needs. This support ensures products meet retail standards without excess capital investment from the business.

Co-packers leverage their industry expertise to streamline the packaging process. This enables businesses to maintain focus on their core activities, such as product development and marketing. With the right partner, companies can quickly adapt to market demands and trends.

A strategic retail packaging strategy is critical for capturing consumer attention. Co-packers understand the nuances of packaging design, functionality, and regulations. They provide businesses with solutions that ensure shelf visibility and compliance, boosting their retail success.

Moreover, co-packers help businesses navigate the complexities of the retail supply chain. They offer logistical support, such as inventory management and distribution, which can be particularly challenging for newcomers. This support helps ensure smooth operations from production to store shelves.

In a competitive retail landscape, efficient operations are key. Co-packers bring the experience and resources to make this possible. They ensure that new entrants can keep up with seasoned competitors without compromising quality or brand integrity.

Maintaining Quality Standards

Quality is a non-negotiable component of retail success. Co-packers play a pivotal role in ensuring products meet the required quality standards. Their facilities are equipped with state-of-the-art technology to maintain consistency.

They implement strict quality control processes at every stage of packaging. This ensures that each product adheres to both industry and brand specifications. Partnering with a co-packer thus safeguards your brand’s reputation, ensuring reliable quality in every unit delivered to retail shelves.

Enhancing Efficiency and Affordability

Efficiency is vital for any retail operation. Co-packers specialize in streamlined processes that maximize productivity. Their experience allows for quick turnaround times, crucial for meeting tight retail timelines.

Additionally, co-packers offer scalable solutions that accommodate fluctuating demand. This flexibility is critical for seasonal spikes or product launches. Businesses can scale up or down without bearing the associated costs of maintaining idle capacity.

Affordability is another advantage of using co-packing services. These partners provide economies of scale unavailable to most new entrants. Businesses benefit from reduced costs per unit, achieving competitive pricing in the retail market. This cost efficiency, coupled with high-quality outputs, establishes co-packers as vital partners in retail success.

Crafting a Retail Packaging Strategy with a Co-Packer

Creating an effective retail packaging strategy requires deep understanding and planning. Partnering with a co-packer can greatly simplify this process. Their expertise is invaluable for aligning packaging with brand identity and consumer expectations.

One must first consider the target audience. Co-packers help identify what appeals to your market segment. They understand the subtleties of design elements like color, size, and texture. These aspects influence consumer purchasing decisions, making them crucial to strategy.

Moreover, co-packers are adept at navigating regulatory requirements. Each industry has specific guidelines that packaging must comply with to avoid legal pitfalls. Expert partners ensure compliance, allowing you to concentrate on product development.

Efficiency goes hand-in-hand with strategy. Co-packers streamline packaging processes, significantly reducing production time. This efficiency helps meet tight retail deadlines and allows quick adaptation to market shifts.

Working with co-packers also opens doors to innovative packaging solutions. These can enhance product functionality and appeal. Innovations in material, design, and technology are regularly introduced to keep packaging fresh and appealing.

Ultimately, the goal is to create a package that resonates with consumers and enhances brand presence. Co-packers provide the resources and knowledge to make that vision a reality, ensuring your product stands out in competitive retail environments.

Key Considerations in Choosing a Retail Co-Packer

Selecting the right retail co-packer involves careful evaluation. The first consideration is their industry experience. A proven track record assures quality outcomes and reliability.

Next, assess their capacity for scalability. Your business must adapt to demand changes promptly. Co-packers with scalable solutions can accommodate this growth without service compromise.

Additionally, consider the technological capabilities of the co-packer. Modern equipment and processes can significantly enhance production efficiency and quality. Thorough due diligence in these areas ensures alignment with your business goals and strategy.

The Role of Custom Retail Packaging in Brand Differentiation

Custom retail packaging is a powerful tool for brand differentiation. It communicates your brand message directly to consumers. Every design aspect speaks volumes about your brand’s values and essence.

Unique packaging designs capture consumer interest. They make your product memorable, encouraging repeat purchases and brand loyalty. It’s not just about aesthetics; functionality plays a critical role too.

Thoughtful packaging design enhances the user experience. Easy-open features, resealability, or eco-friendly materials can set your product apart. Partnering with a co-packer who understands these nuances is essential for leveraging custom packaging effectively.

These elements ensure that your product not only stands out on the shelf but also delivers value to your consumers, fostering a positive brand relationship.

Transitioning to Co-Packing Services

Shifting from in-house production to co-packing services can be daunting. However, it’s a strategic move that offers various benefits. Understanding how to manage this transition is crucial for success.

The process requires a thorough evaluation of your current production capabilities. Identify gaps that co-packing can fill. Analyze which operations would benefit most from outsourcing to improve quality and efficiency.

Communication with potential co-packers is vital. Lay out your expectations and requirements clearly. This dialogue ensures that both parties are aligned and can deliver on the agreed objectives.

Selecting the right partner is the next step. Look for a co-packer whose strengths complement your needs. A partner with industry knowledge and innovative capabilities can elevate your product offering.

Finally, monitor and evaluate the co-packing process regularly. This oversight helps maintain quality standards and ensures that the partnership remains beneficial. Continuous improvement is key to achieving optimal results in your co-packing endeavors.

The Process of Moving from In-House to Outsourced Production

Transitioning to outsourced production involves several key stages. Begin by assessing your product’s specific requirements. Determine which areas of production are best suited for co-packing.

Next, conduct thorough research to identify potential co-packers. Evaluate them based on their experience, capacity, and technological capabilities. Review case studies or client testimonials to gauge their track record.

Once you’ve chosen a partner, establish clear communication channels. This includes setting expectations regarding quality, timelines, and costs. Effective communication is essential to ensure that your vision is brought to life without compromise.

Understanding Co-Packing Costs and Scalability

Understanding the cost structure of co-packing is essential. Costs can vary based on factors like production volume, packaging complexity, and material choice. It’s critical to evaluate these variables to manage budgets effectively.

Scalability is another important consideration. Your chosen co-packer should be capable of adjusting production levels to meet demand fluctuations. This flexibility ensures that your business can grow without facing logistical constraints, allowing for smooth scaling as your market presence expands.

Effective Communication and Negotiation with Co-Packers

Building a successful relationship with a co-packer hinges on effective communication. It involves more than just exchanging information. It’s about establishing a mutual understanding and shared objectives.

Start by setting clear, achievable goals. Define what success looks like for both parties. Ensure that these objectives are communicated early on to avoid misunderstandings later.

Regular meetings are critical. They provide opportunities to discuss progress, address issues, and adapt strategies as needed. Being proactive in communication helps keep projects on track.

Transparency is key to building trust. Share necessary data and insights openly. This openness encourages your co-packer to reciprocate, leading to a more collaborative partnership.

Finally, be receptive to feedback. Your co-packer may offer valuable insights based on their expertise. Considering their input can lead to improved processes and outcomes.

Strategies for Clear and Productive Co-Packer Relationships

To foster productive co-packer relationships, clarity is essential. Begin by outlining all project specifics in detail. This includes timelines, quality standards, and volume expectations.

Consistency in communication helps maintain alignment. Choose reliable communication channels and stick to them. Whether via email or regular meetings, consistency prevents miscommunications.

Adaptability is also crucial. The ability to adjust to changes in the market or production requirements strengthens collaboration. It ensures that both parties can respond to new challenges effectively.

Tips for Negotiating Co-Packing Contracts

Negotiating co-packing contracts requires attention to detail. Firstly, ensure all terms are explicitly stated. This reduces ambiguity and potential disputes down the line.

Additionally, focus on building a fair agreement. Both parties should benefit from the contract terms. Fairness fosters a long-term, positive relationship, aligning mutual interests for sustained success.

Leveraging Co-Packing for Market Testing and Product Launches

Co-packers play a pivotal role in market testing. Their expertise allows businesses to introduce products with confidence. They ensure that packaging aligns with consumer expectations and stands out on retail shelves.

For startups, using a co-packer can mitigate risks. They provide the flexibility to produce smaller batches. This enables testing different packaging designs or product variations without a large upfront investment.

Product launches also benefit significantly from co-packing services. Co-packers facilitate a streamlined production process. Their established networks and expertise ensure that products reach the market quickly and efficiently.

Co-packers can also handle fluctuations in demand. During a launch, unexpected demand spikes may occur. With a reliable co-packer, scaling production up or down becomes manageable, ensuring timely fulfillment.

The Role of Co-Packers in Inventory and Logistics Management

Inventory management is a crucial aspect of successful retail operations. Co-packers can help optimize this process. They provide insights into stock levels and manage supply chain complexities.

Logistics management is another area where co-packers excel. Their established distribution channels and expertise ensure efficient product flow. This results in reduced lead times and improved delivery accuracy.

Value-Added Services and Turnkey Solutions

Co-packers offer more than just packaging; many provide value-added services that enhance product appeal. These can include graphic design support, labeling solutions, or even assistance with regulatory compliance.

Turnkey solutions simplify the production process. A single partner manages all aspects, from sourcing materials to final packaging. This comprehensive approach saves time, reduces complexity, and allows businesses to focus on growth.

Ensuring Success with Your Retail Co-Packer

Success in co-packing partnerships hinges on strong collaboration. Establishing a clear line of communication with your co-packer is key. This ensures alignment on goals and expectations from the outset.

Prioritize transparency in all dealings. Open discussions about production capabilities and limitations prevent misunderstandings. Clarity fosters trust, which is vital for a successful partnership.

Quality assurance cannot be overlooked. Implement robust checks at various production stages. Ensuring product quality aligns with brand standards is paramount for retail success.

Timeliness is another crucial factor. Meeting deadlines affects the entire supply chain. Effective scheduling and proactive planning help keep timelines on track.

Scalability should also be factored into your strategy. As demand grows, your co-packer should be equipped to scale accordingly. This requires a detailed understanding of production processes and capacity.

Regularly review the partnership to identify areas for improvement. Maintaining a feedback loop allows for continuous enhancement of the relationship. Celebrate successes and address any challenges collaboratively for mutual growth.

Quality Assurance and Meeting Deadlines

Quality assurance is fundamental to any co-packing relationship. Your co-packer should have stringent quality control measures. Inspect samples at different stages to ensure consistency and adherence to standards.

Meeting deadlines is equally critical. Timelines must be clear and realistic from the start. Collaboration with your co-packer in planning production schedules ensures timely delivery, maintaining retail supply chain flow.

Managing Multiple Projects and Vendor Relationships

Handling multiple projects requires strategic oversight. Centralizing communication through a single point of contact can streamline processes. This approach prevents miscommunication and ensures consistency across projects.

Maintaining vendor relationships is as important. Regular updates and open dialogue with all vendors foster a positive environment. This helps identify potential issues early and addresses them proactively.

Measuring the Success of Co-Packing Partnerships

Evaluating the success of co-packing partnerships involves several factors. Regularly assess production efficiency and quality metrics. These indicators provide insights into the partnership’s operational effectiveness.

Feedback mechanisms are valuable in performance evaluation. Gathering input from all stakeholders highlights areas of strength and needed improvements. Use this information to refine processes, enhancing the partnership over time.

Navigating the retail landscape is complex, but partnering with the right co-packer can make all the difference. From packaging design and production to inventory management and logistics support, co-packers help brands streamline their operations and meet retail standards.

Econo-Pak specializes in high-volume dry food packaging, offering turnkey co-packing solutions that help brands scale efficiently and enter new markets with confidence. With decades of experience, robust quality control systems, and the capacity to handle complex projects, Econo-Pak is ready to support your retail expansion.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

The Smart Way to Manage Airline Co-Packing, Imports, and Tariff Challenges

Comments Off on The Smart Way to Manage Airline Co-Packing, Imports, and Tariff ChallengesSupply chains have become increasingly complex. Food brands must stay ahead of shifting regulations, evolving import strategies, and airline-specific requirements. At Econo-Pak, we offer turnkey co-packing and contract manufacturing solutions that help brands navigate these challenges efficiently.

From airline packaging compliance to mitigating tariff impacts through U.S.-based final packaging, our expertise ensures smooth operations for food brands looking to scale.

Airline-Approved Co-Packing: Meeting Strict Standards

The airline industry has stringent requirements for food packaging, from oxygen level testing to specific pack-out configurations. Econo-Pak is already audited and approved by major airlines, making it easier for food brands to integrate their products into in-flight offerings.

- Regulatory compliance: We meet FDA and airline-specific standards, ensuring all packaged goods pass necessary audits.

- Flexible packaging options: Whether airlines require inflated or deflated bags, air gas flushing, or modified atmosphere packaging (MAP), we can handle it.

- High-output capabilities: Our automated production lines efficiently meet high-volume airline demands.

For food brands looking to secure airline distribution, working with an airline-approved co-packer like Econo-Pak eliminates the guesswork and speeds up market entry.

Mitigating Tariff Impacts: Importing Bulk, Packaging in the U.S.

Changing tariffs have made importing finished packaged goods more expensive, leading many brands to ship bulk ingredients and complete packaging domestically. Econo-Pak provides a cost-effective solution for brands looking to avoid excessive duties while maintaining international sourcing.

- Bulk unloading & inventory management: We can receive shipments from multiple 40-foot high cube containers, inventory raw materials, and manage traceability.

- Testing & certification: Imported goods often require additional testing—our team ensures all products meet U.S. regulatory and quality standards.

- Efficient final packaging: Whether products need date coding, UPC labeling, or pack-out customization, we handle the final packaging domestically to help brands optimize costs.

By leveraging this strategy, brands can lower tariff costs while ensuring their products meet U.S. compliance and distribution requirements.

Optimizing Import Strategies: Multi-Channel Distribution

For brands that import pre-packaged goods, Econo-Pak also offers solutions to optimize distribution. Many importers maximize efficiency by shipping full containers of identical products but then need to reconfigure pack-outs for different retail channels.

- Channel-specific packaging: We create custom pack-outs for Walmart, dollar chains, convenience stores, and more.

- GS1 & ASN management: We handle barcode labeling and tracking for seamless retailer integration.

- Direct-to-retail distribution: We coordinate outbound logistics to ensure products reach multiple sales channels efficiently.

This approach allows brands to retain cost-effective overseas production while customizing products for varied retail requirements in the U.S.

Partner with Econo-Pak for Scalable Solutions

Whether you’re navigating airline compliance, tariff challenges, or multi-channel distribution, Econo-Pak is equipped to handle high-volume, complex packaging needs. Our turnkey contract packaging solutions provide a seamless way to streamline supply chains, reduce costs, and accelerate growth.

Looking for a strategic co-packing partner to help optimize your import and airline packaging strategies? Contact Econo-Pak today to discuss how we can support your brand.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

The Unstoppable Growth of Contract Food Packaging and Private Labeling

Comments Off on The Unstoppable Growth of Contract Food Packaging and Private LabelingThe food industry is evolving at record speed, and contract food packaging has become essential for brands looking to stay ahead. With shifting consumer preferences, rising sustainability demands, and new retail opportunities, packaging isn’t just about protecting a product—it’s a strategic tool that can drive growth and increase market share.

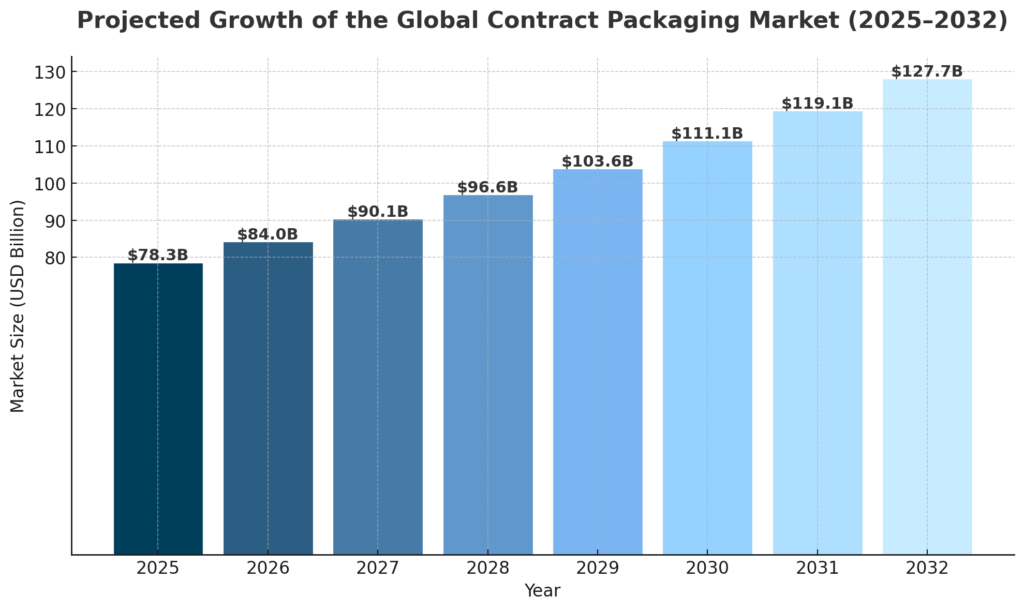

Consider this: the global contract packaging market is projected to reach $117 billion by 2030, growing at a 7% CAGR, as more companies lean on experts to streamline operations and reduce costs.

For brands searching for “food co packer near me” or exploring private label packaging to break into new markets, understanding the latest innovations can give you a competitive edge.

In this article, we’ll break down how to choose the right partner, key differences between co-packing and co-manufacturing, and what’s trending in packaging technology—all with insights designed for packaging managers, startup CEOs, and contract manufacturing leaders.

What is contract food packaging?

Contract food packaging is the behind-the-scenes hero of the supply chain, allowing brands to outsource their packaging processes so they can focus on scaling, marketing, and product development.

By working with a contract packager, companies benefit from:

- Flexible production runs

- Reduced capital investment in packaging automation and machinery

- Expertise in regulatory compliance

- Faster speed to market

And with over 50% of CPG companies now outsourcing part of their packaging operations, it’s clear that scalability and cost efficiency are driving adoption across the industry.

Co-packing vs. co-manufacturing: What’s the difference?

For anyone looking into “co packers near me,” it’s important to understand the distinction:

While co-packing is ideal if you have a finished product that needs packaging, co-manufacturing is perfect if you need help producing the product itself from raw ingredients to final packaging.

Why private label packaging is a growth strategy

Private label packaging is booming. Private label food sales hit $271 billion in 2024, up 14% from 2023, in the U.S. alone, driven by consumers seeking quality at a better price. For brands, private label packaging is more than just slapping a name on a product—it’s about crafting a unique identity and standing out on crowded shelves.

Benefits of private label packaging include:

- Customizable designs that align with brand values

- Sustainable material options to appeal to eco-conscious buyers

- Faster entry into new retail spaces, like club stores and convenience chains

The role of automation and robotics in contract packaging

Automation is no longer a luxury; it’s the standard to achieve high-volume production with maximum efficiency. In contract food packaging, automation delivers:

- Precision and consistency in every run

- Real-time quality control

- Scalability for high-volume demand

As product demand fluctuates, automated lines help businesses stay nimble without sacrificing quality.

Why location matters when searching for “food co packer near me”

Looking for “co packers near me” isn’t just about convenience—it’s a strategic move. A local food co packer helps reduce freight costs and speed up delivery timelines, which is crucial when 58% of consumers have paid more for faster delivery, with most having paid extra for next-day (69%) and same-day delivery (61%).

Regional packers also understand local regulations, climate considerations, and retailer preferences, making them valuable partners for expanding into specific markets.

Turnkey contract packaging: One partner, total support

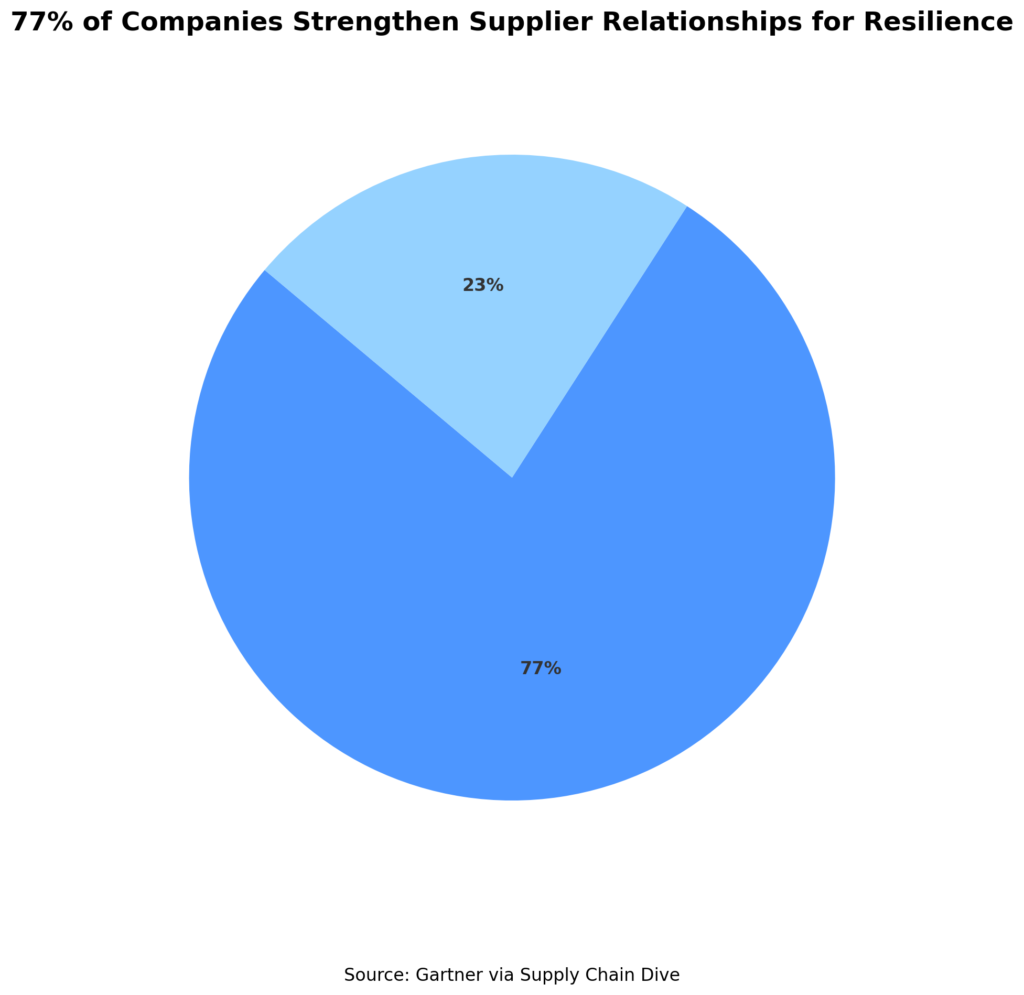

Brands are increasingly turning to turnkey contract food packaging partners that handle everything from sourcing materials to final distribution. In fact, 77% of companies are investing in deeper and more collaborative supplier relationships to enhance resilience and agility.

Turnkey services offer:

- A dedicated team to your project

- Material sourcing

- Blending, seasoning, and grinding services

- Packaging, warehousing, and shipping

The result? Simpler project management and faster go-to-market timelines.

The future of contract packaging

Sustainability, technology, and flexibility are driving the next wave of innovations in contract packaging:

🔹 Smart packaging with QR codes for traceability

🔹 Biodegradable films to meet eco goals (with 60% of consumers preferring recyclable packaging)

🔹 Digital printing for hyper-personalized product runs

By staying ahead of these trends and partnering with experienced co-packers, brands can future-proof their operations and capitalize on shifting market demands.

Why choose Econo-Pak as your private label co-packer?

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

Meeting Airline Audit Standards for In-Flight Snack Co-Packing

Comments Off on Meeting Airline Audit Standards for In-Flight Snack Co-PackingAirline food and snack programs require a level of precision and consistency that few industries can match. Every product served in-flight must meet strict safety standards, fit within tight packaging guidelines, and hold up to the challenges of air travel—all while satisfying passengers at 30,000 feet.

For food brands selected to supply airline snack programs, partnering with a co-packer that meets airline standards is critical. That’s why Econo-Pak is regularly audited and approved by all major U.S. airlines—ensuring we have the certifications, processes, and capabilities needed to support the brands fueling in-flight menus.

Meeting the highest standards in the sky

Airline audits are thorough. From food safety and allergen control to traceability and packaging integrity, every detail of our operation is reviewed to confirm compliance with airline specifications and federal regulations.

Econo-Pak maintains industry-leading certifications like SQF and FDA registration, and we pair these with decades of experience producing snack products designed for long shelf life and stable performance in transit. For airline packaging programs, this means peace of mind that every pouch, packet, and portion is produced with care.

Co-packing solutions built for airlines

The needs of airline foodservice go far beyond basic packaging. Our team works closely with brands and airline suppliers to create co-packing solutions that address key challenges, including:

- Portion control: Snacks must be consistent, lightweight, and sized for individual servings.

- Shelf stability: Products often require extended shelf life without sacrificing quality.

- Packaging performance: Materials need to hold up during transit and on board while still being easy for passengers to open.

- Scalability: Airlines operate at high volumes, and their snack programs need suppliers who can keep up.

From mixed nuts and trail mixes to cookies, crackers, and hard candies, Econo-Pak has the capabilities to keep airline snack programs running smoothly across hundreds of daily flights.

Supporting growth for airline suppliers

We also understand that the brands behind in-flight snack programs are always looking ahead—whether that’s launching new products, expanding into international routes, or responding to changing passenger preferences. With high-capacity lines, a wide range of packaging options, and a responsive support team, we help our partners scale without compromising on quality.

Ready to take off?

If you’re looking for a co-packing partner who’s already been vetted by the world’s leading airlines, Econo-Pak is ready to help. Contact us today to learn more about our experience with airline snack programs and how we can support your next project.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

Importance of Dielines in Quoting Co-Packing Projects

Comments Off on Importance of Dielines in Quoting Co-Packing ProjectsPrecision is everything in co-packing. Every element of a packaging project—materials, dimensions, sealing, labeling—affects production efficiency and costs.

One of the most critical factors in providing an accurate co-packing quote is the dieline. Without it, pricing and feasibility assessments become challenging, often leading to delays, cost discrepancies, or unexpected production issues.

What is a dieline?

A dieline is a technical blueprint that outlines the shape, size, and folding lines of a package. It acts as a guide for both structural design and printing, ensuring that all components fit together correctly. Dielines in packaging help define key specifications such as:

Cut lines – Indicating where the material will be cut.

Fold lines – Showing how the package will be assembled.

Bleed areas – Ensuring designs extend beyond the trim line to prevent unprinted edges.

Safe zones – Marking areas where important graphics or text should be placed to avoid being cut off.

Why dielines in packaging matter in co-packing quotes

Providing a dieline upfront allows co-packers to generate accurate and reliable co-packing quotes by:

1. Determining material requirements

Without a dieline, it’s difficult to estimate the exact amount of packaging material needed. A properly defined dieline ensures that material waste is minimized and the most cost-effective options are used.

2. Assessing machine compatibility

Co-packers need to determine whether existing machinery can handle the package dimensions and structure. Certain package designs may require custom tooling or specialized packaging equipment, impacting the overall project cost.

3. Calculating labor and production time

The complexity of a dieline affects how a package is assembled. A simple tuck-top box requires far less time and labor than a multi-panel, intricate structure. Having a dieline helps estimate labor requirements and streamline production timelines.

4. Avoiding delays and miscommunications

Without a dieline, assumptions must be made about packaging dimensions and layout, which can lead to costly mistakes or production delays. Clear, precise dielines eliminate guesswork and ensure all stakeholders are aligned from the start.

What happens if a dieline isn’t provided?

If a dieline isn’t available, co-packers must rely on estimations, often leading to:

Overestimated or underestimated costs – Affecting project budgets and profitability.

Production inefficiencies – Requiring additional time for adjustments or redesigns.

Packaging errors – Leading to improper fits, structural failures, or misaligned prints.

How to ensure a smooth quoting process

For brands looking to receive an accurate co-packing quote, providing a dieline upfront is key. Here are some best practices:

Work with your designer or packaging supplier to create a production-ready dieline.

Ensure dielines are in vector formats (such as AI, PDF, or EPS) for precision and scalability.

Include all technical details like dimensions, material specifications, and finishing requirements.

Communicate any modifications early in the process to prevent rework or cost increases.

Send us your project today

Dielines in packaging are more than just templates—they are essential tools for accurate co-packing quotes, efficient production, and successful co-packing projects. By providing clear and detailed dielines upfront, brands can streamline the quoting process, avoid unexpected costs, and ensure their packaging meets both functional and aesthetic expectations.

For brands looking to scale with contract packaging, having a dieline ready is one of the first steps toward a seamless and cost-effective partnership.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

Finding the Right Candy Co-Packer: What Brands Need to Know

Leave a CommentThe candy industry is evolving, with brands looking for efficient, scalable ways to bring their products to market. Whether launching a new line of gummies, chocolates, or hard candies, partnering with a candy co-packer can streamline production while maintaining quality.

But how do you find the right co-packer for your brand? And what should you look for when evaluating potential partners?

What is a candy co-packer?

A candy co-packer (or contract packager) is a third-party company that handles the packaging and sometimes the production of candy products. They work with brands that want to scale without investing in their own manufacturing and packaging equipment.

A reliable co-packer ensures that products meet food safety regulations, maintain quality, and are ready for retail or wholesale distribution.

The benefits of using a candy co-packer

For candy brands, outsourcing packaging (and in some cases, manufacturing) to a co-packer offers several advantages:

Key factors to consider when choosing a candy co-packer

Not all candy co-packers are the same, and selecting the right partner is crucial for product success. Here are a few key considerations:

Packaging capabilities

- Can they handle the packaging format you need (e.g., stand-up pouches, flow wraps)?

- Do they offer labeling and retail-ready solutions?

Food safety and quality standards

- Are they certified for food safety programs like SQF?

- Do they have rigorous quality control measures in place?

Experience with candy products

- Have they worked with similar candy types before?

- Do they understand the unique challenges of handling ingredients like chocolate, gummies, or sugar-based confections?

Minimum order quantities (MOQs)

- Does their production volume align with your needs?

- Can they support your growth as demand increases?

Turnaround time and lead times

- How quickly can they fulfill an order?

- Do they have the capacity to meet tight deadlines for retail launches?

Additional services

Do they offer secondary packaging like multi-packs or promotional bundling?

Can they help with logistics, warehousing, or distribution?

Is a candy co-packer the right choice for your brand?

For brands looking to scale efficiently, partnering with a candy co-packer can be a strategic move. It allows you to get your products into retail stores, e-commerce platforms, and wholesale distribution channels without the burden of in-house production.

If you’re exploring co-packing options for your candy brand, working with an experienced partner ensures quality, compliance, and efficiency.

Looking for a trusted candy co-packer? Send Econo-Pak your project details below to see how we can help bring your product to market with fixed-cost pricing.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

Co-Packing for Organic and Non-GMO Food Products

Leave a CommentCo-packing plays a pivotal role in the food industry, especially for brands focused on organic and non-GMO products. According to the Organic Trade Association, sales of organic food in the U.S. grew by 12.4% in 2020, reaching a record $62 billion, while demand for non-GMO products continues to rise as consumers prioritize transparency and health (Organic Trade Association, 2021).

As the demand for natural, clean-label food continues to grow, finding the right organic co-packer or non-GMO co-packer becomes essential for maintaining quality and compliance while scaling operations. This article explores the importance of organic co-packing and non-GMO co-packing, key considerations when choosing a partner, and the benefits of outsourcing production.

What is Co-Packing?

Co-packing, or contract packaging, involves outsourcing the production and packaging of products to a specialized third party. For organic and non-GMO food brands, co-packing ensures consistent quality and compliance with stringent certification standards.

Organic Co-Packing Defined

Organic co-packing refers to the process of manufacturing and packaging food products in facilities that are certified organic. This means adhering to USDA organic standards, avoiding synthetic chemicals, and ensuring environmentally sustainable practices.

Non-GMO Co-Packing Explained

Non-GMO co-packing involves producing food items that are free from genetically modified organisms (GMOs). Co-packers must source non-GMO ingredients and adhere to certification guidelines, such as those set by the Non-GMO Project.

Benefits of Organic and Non-GMO Co-Packing

Outsourcing production to a certified organic co-packer or non-GMO co-packer offers several advantages for food brands:

1. Access to Expertise and Compliance

Certified co-packers are well-versed in organic and non-GMO standards, ensuring compliance with regulations and certifications.

2. Cost Efficiency

Partnering with a co-packer eliminates the need for brands to invest in expensive equipment, facilities, and staff. Additionally, the cost of maintaining certifications, such as USDA Organic or Non-GMO Project Verified, is managed by the co-packer, further reducing financial burdens for brands.

3. Scalability

As demand for organic and non-GMO products increases, co-packers help businesses scale without compromising quality.

4. Quality Assurance

Experienced co-packers implement rigorous quality control measures to maintain the integrity of organic and non-GMO products. For instance, Econo-Pak is SQF Level 3 certified, ensuring the highest standards in food safety and quality.

Key Considerations When Choosing a Co-Packer

Selecting the right organic co-packer or non-GMO co-packer is critical for brand success. Here are key factors to evaluate:

1. Certification

Ensure the co-packer holds relevant certifications, such as USDA Organic and Non-GMO Project Verified.

2. Experience

Look for co-packers with a proven track record in organic and non-GMO food production.

3. Facility Capabilities

Verify that the facility meets your production and packaging needs while adhering to organic and non-GMO guidelines.

4. Transparency

Choose a partner who is transparent about ingredient sourcing, processes, and compliance standards.

The Process of Organic and Non-GMO Co-Packing

The process of organic and non-GMO co-packing begins with ingredient sourcing. Co-packers source certified organic or non-GMO ingredients, maintaining transparency across the supply chain. Manufacturing takes place in certified facilities adhering to strict organic and non-GMO standards. Packaging follows, often utilizing eco-friendly materials to align with sustainable practices. Finally, extensive quality control measures ensure compliance with certifications and brand standards, maintaining the integrity of the finished product.

Challenges in Organic and Non-GMO Co-Packing

Despite its advantages, co-packing for organic and non-GMO products comes with challenges. Certification costs, such as those for USDA Organic or Non-GMO Project Verified, can be significant, impacting overall expenses. Additionally, sourcing certified ingredients poses a challenge due to market fluctuations and limited availability. Lastly, finding co-packers with the necessary certifications and expertise can be competitive, making the selection process critical for success.

Why Co-Packing is a Strategic Advantage

Organic and non-GMO co-packing is a strategic choice for food brands looking to scale while maintaining quality and compliance. By partnering with certified co-packers, businesses can meet the growing demand for natural, sustainable products without the logistical burden of in-house production.

FAQs

1. What certifications should an organic co-packer have?

An organic co-packer should hold USDA Organic certification and comply with the National Organic Program (NOP) standards.

2. How do I verify a co-packer’s non-GMO credentials?

Look for Non-GMO Project Verified certification and request documentation of compliance.

3. Can a co-packer handle both organic and non-GMO products?

Yes, many co-packers specialize in both organic and non-GMO production, but it’s essential to verify their certifications.

4. What are the cost implications of using a co-packer?

Costs vary based on production volume, certifications, and the complexity of your product. Co-packing is generally more cost-effective than in-house production.

5. How do I find the right co-packer for my brand?

Research certified co-packers, review their experience, visit their facilities, and ensure they align with your brand’s values and goals.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.