Why is Flexibility in Packaging Lines Critical in Seasonal Demand?

Comments Off on Why is Flexibility in Packaging Lines Critical in Seasonal Demand?

When seasonal demand hits, brands must adapt quickly. From holiday snacks to limited-edition flavors, product demand can surge overnight. The ability to respond fast without slowing production or compromising quality depends on one key factor: flexibility! Econo-Pak does this right.

Meeting Seasonal Spikes Efficiently

Seasonal peaks can put enormous pressure on packaging operations. A flexible packaging line can adjust run sizes, materials, and formats to match changing needs. This means products reach store shelves faster, helping brands stay competitive and meet consumer expectations on time.

Reducing Downtime and Costs

Rigid systems slow down when new SKUs or packaging sizes are introduced. Flexible lines minimize these interruptions by allowing quick changeovers and streamlined setups. This reduces waste, lowers downtime, and maximizes output especially during periods when every minute counts.

Supporting Brand Innovation

Seasonal launches are often opportunities to test new flavors, designs, or promotions. A flexible packaging system allows brands to experiment without large production commitments. This agility encourages innovation and helps brands capture market attention with limited-run or specialty items.

How Econo-Pak Delivers the Flexibility You Need

At Econo-Pak, flexibility is built into everything we do. Our advanced equipment can accommodate a wide range of packaging formats, from flow wrapping and pouches to cartons and variety packs. With a highly trained team and scalable operations, we can adjust production quickly to meet any seasonal surge.

Whether you are ramping up for the holidays or planning a promotional release, Econo-Pak ensures efficiency, speed, and quality every step of the way.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

Why Is End to End Procurement Cost Effective?

Comments Off on Why Is End to End Procurement Cost Effective?

When brands choose a co-packer, they want more than production capacity. They want reliable supply, faster timelines, and cost control. End to end procurement helps deliver all three by managing every part of the sourcing process from vendor selection to delivery.

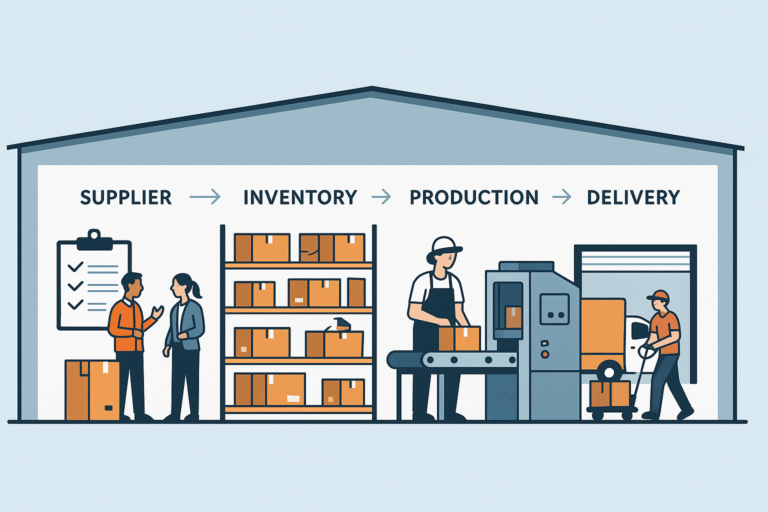

What Is End to End Procurement?

End to end procurement means the co-packer oversees material sourcing from start to finish. This includes supplier negotiations, inventory planning, logistics, and delivery timing. Instead of working with multiple vendors, brands benefit from one partner who coordinates the entire supply chain.

How It Improves Stability

By working directly with trusted suppliers, procurement stays aligned with production schedules. This reduces the risk of material shortages, delays, or last-minute pricing issues. Brands gain more visibility and smoother planning, even when market conditions shift.

Time Savings

With centralized sourcing, brands no longer need to manage supplier quotes, contracts, or logistics on their own. This cuts down on communication steps and speeds up production launches. The result is a faster path to market and less time spent on administration.

Cost Reduction

Because a co-packer negotiates at scale, brands benefit from better pricing. Costs are also reduced through fewer freight delays, less excess inventory, and stronger long-term supplier agreements. Consolidated purchasing power leads to measurable savings. Here at Econo-Pak we offer a fixed cost solution.

Why Econo-Pak Is the Right Partner

Econo-Pak brings years of procurement experience and strong supplier relationships that help protect brands from supply chain disruption. Our team manages sourcing in direct alignment with production timelines so materials arrive when they are needed and at the best possible value. We streamline communications, handle negotiations, and maintain pricing consistency so brands can scale without added complexity.

With Econo-Pak as your procurement partner, you gain efficiency, cost stability, and peace of mind through a fully supported sourcing process from beginning to end.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

How Does Flow Wrapping Keep Products Fresh and Shelf Ready?

Comments Off on How Does Flow Wrapping Keep Products Fresh and Shelf Ready?

When it comes to food packaging, freshness and presentation matter most. Flow wrapping is one of the most reliable and efficient packaging methods for protecting food products, extending shelf life, and ensuring a clean, consistent look on store shelves. At Econo-Pak, our advanced flow wrapping systems are designed to maintain quality while maximizing efficiency.

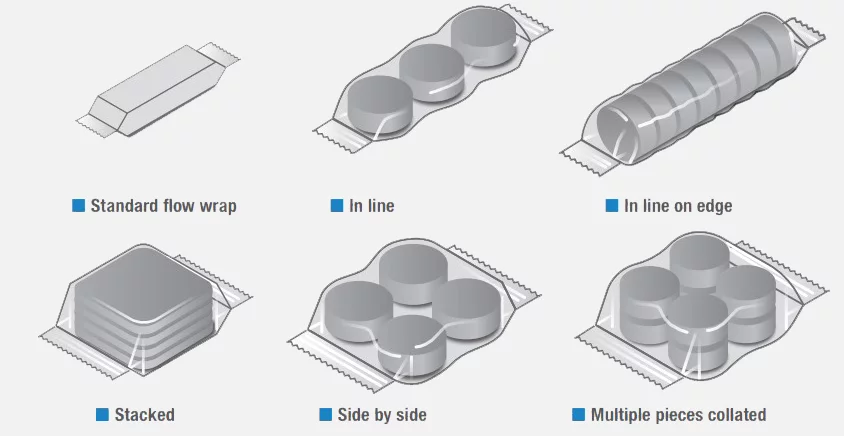

What Is Flow Wrapping?

Flow wrapping, also known as horizontal form-fill-seal packaging, is a process where a continuous film is formed around a product, sealed on the sides, and then cut into individual packages. This method creates a tight, protective barrier that keeps out moisture, air, and contaminants. The result is a hygienic, attractive package that consumers can trust.

Freshness That Lasts

One of the key benefits of flow wrapping is its ability to preserve freshness. By sealing products quickly and securely, the process minimizes exposure to oxygen and humidity, two major factors that lead to spoilage. Whether it’s snacks, baked goods, or dry mixes, flow wrapping locks in flavor, aroma, and quality from production to consumption.

Shelf-Ready and Consumer-Friendly

Beyond protection, flow wrapping delivers a polished, shelf-ready appearance. The consistent size, smooth seals, and clear or branded film options help products stand out at retail. Flow-wrapped packages are also easy to open, resealable when designed with features like zippers, and ideal for single-serve or multi-pack formats. This flexibility makes them perfect for today’s on-the-go consumers.

Efficiency That Supports Your Brand

At Econo-Pak, our flow wrapping lines are built for speed and accuracy. With automated systems that handle high volumes without compromising quality, we help food brands meet demand while maintaining freshness and presentation. Our process also reduces material waste and supports sustainability goals through efficient film usage and recyclable packaging options.

Why Choose Econo-Pak for Flow Wrapping

Econo-Pak specializes in customized flow wrapping solutions for a wide range of dry food products. Our team ensures every package meets strict quality and safety standards, backed by certifications like SQF Level 3 and FDA compliance. From flow wrapped biscuits, cookies, and much more, we deliver packaging that keeps your products fresh, safe, and shelf-ready.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

How Do You Choose the Right Co-Packer for Your Food Brand?

Comments Off on How Do You Choose the Right Co-Packer for Your Food Brand?How to Choose the Right Co-Packer for Your Food Brand

Choosing the right co-packer is one of the most important decisions a food company can make. The right partner protects your brand, keeps costs under control, and helps you scale. The wrong one can lead to delays, quality issues, or missed opportunities. Here is what to look for when evaluating a co-packing partner and why Econo-Pak is the ultimate solution.

Food Safety and Certifications

Food packaging companies must meet the highest standards of safety and compliance. Certifications like SQF Level 3, FDA registration, GMP, HACCP, gluten free, kosher, organic, and Sedex prove a co-packer is equipped to handle your products responsibly. Econo-Pak holds all of these certifications and maintains strict quality testing every hour to ensure consistency. With no history of product recalls, their record speaks for itself.

Capacity and Flexibility

As your brand grows, your co-packer should grow with you. Econo-Pak operates more than 200 packaging machines inside a 240,000 square foot facility with a major expansion underway. Whether you need pouch filling, cartoning, flow wrapping, or variety packs, their scale and technology give you speed and flexibility without bottlenecks.

Cost Transparency

Hidden fees can eat away at margins. That is why Econo-Pak offers a fixed price model so brands know exactly what to expect. Transparent pricing and defined project scopes allow you to plan confidently and avoid costly surprises.

Proven Experience

With more than 40 years of co-packing expertise, Econo-Pak has supported both startups and Fortune 500 food companies. Trusted by household brands and praised for exceeding KPIs in quality and efficiency, they have the track record to back up their claims.

Econo-Pak: The Ultimate Co-Packing Partner

When choosing a co-packer, look for certifications, scale, transparent pricing, and proven reliability. Econo-Pak delivers all of that and more. Their commitment to food safety, large scale capabilities, and dedication to customer success make them the go-to co-packing solution for dry food brands ready to grow.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

Why is Portion Controlled Packaging Essential for Today’s Consumers?

Leave a Comment

Meeting today’s consumer expectations

Consumers are more conscious than ever about convenience, health, and value. They want products that fit their busy lifestyles, help manage portions, and deliver consistent quality. Portion controlled packaging is one of the most effective ways food brands can address these evolving demands. By offering products in single-serve or pre-measured sizes, companies not only meet shopper expectations but also strengthen their position in competitive markets.

Convenience and on-the-go lifestyles

From commuters to parents packing lunches, convenience is a driving factor in consumer decisions. Portion controlled packs make it easy for people to grab exactly what they need without extra effort. Whether it’s a snack-sized bag of pretzels, single-serve cookies, or a ready-to-pour seasoning packet, this format aligns with the fast-paced lives of today’s consumers.

Supporting health and wellness goals

Health-conscious shoppers are increasingly mindful of calories and portion sizes. By pre-measuring servings, portion controlled packaging helps consumers stick to dietary goals without sacrificing enjoyment. This builds trust and loyalty, as shoppers can confidently choose products that support healthier choices.

Reducing food waste

Another key advantage is minimizing waste. Pre-portioned packaging ensures consumers open only what they plan to eat, extending freshness and reducing the chance of spoiled or wasted food. This also aligns with growing sustainability expectations, showing that brands care about efficiency and responsibility.

Expanding commercialization opportunities

For manufacturers, portion controlled packaging opens the door to new channels. Products in smaller pack sizes are ideal for vending machines, convenience stores, airlines, and food service markets. They also fit well into variety packs for supermarkets and club stores, creating more opportunities to reach diverse audiences.

How Econo-Pak helps

At Econo-Pak, we specialize in high-volume portion controlled packaging for snacks, dry foods, and more. With over 200 state-of-the-art machines and more than 30 packaging formats, we provide flexibility to meet demand across markets. From supermarkets and club stores to vending, convenience, and food service, our portion controlled solutions help brands grow while delivering exactly what consumers want.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

What Is the Role of Automation in Achieving Volume Flexibility?

Leave a Comment

In today’s food industry, demand isn’t always predictable. One week, a brand might need a small run for a seasonal product; the next, they could be scaling up to meet nationwide distribution. That’s where volume flexibility comes in—and automation plays the starring role.

At Econo-Pak, automation isn’t just about speed. It’s about building a system that can scale, adapt, and deliver—no matter the project size.

Flexible Machinery for Changing Demands

With over 200 state-of-the-art packaging machines, our automated systems can shift between packaging types quickly. From pouches to flow wrapping to volume filling, flexibility is built into our operations. As our Maintenance Manager, Jared Ellsworth, puts it: “We change things over on a daily basis.”

That means clients don’t have to worry about whether we can handle their product—we can pivot to meet the need.

Scaling Smart: From Manual to Automated

Not every project starts with full automation. For many new SKUs, we begin with manual runs to better understand product handling and throughput. Once the process is refined, automation is introduced to increase speed, precision, and efficiency.

This step-by-step approach lets brands grow without the upfront strain of large-scale automation—while still knowing the option is there when they need it.

The Power of Robotics

Automation at Econo-Pak isn’t just about machines; it’s about robotics, too. Collaborative robots (cobots) and pick-and-place systems help us handle repetitive tasks like sorting, loading, and sealing.

The result? Faster turnaround times, fewer errors, and reduced strain on human workers. Robotics make it possible to adapt packaging lines to different volumes and formats without losing efficiency.

Quality and Control at Every Volume

Automation also ensures that quality never slips—whether we’re producing a short run or millions of units. With in-house filling operations, real-time monitoring, and rigorous checks, every package meets the highest standards.

This is especially important when volumes fluctuate, since consistency is what keeps food brands trusted in the market.

Continuous Investment in Flexibility

We don’t stop at “good enough.” Each year, Econo-Pak invests in new equipment—from bag-in-box bagging to advanced cartoning lines—that push automation further. These upgrades allow us to serve more clients, meet more formats, and handle higher volumes without compromising on quality.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

VFFS (Vertical Form Fill Seal): Choosing Films and Materials for Dry Foods

Leave a Comment

Vertical Form Fill Seal (VFFS) machines are one of the most efficient solutions for packaging dry foods. From snacks and cereals to powders and mixes, this technology forms, fills, and seals bags in a single streamlined process. To achieve the best results, choosing the right films and materials is essential. At Econo-Pak, we specialize in helping food brands make the right packaging decisions while delivering consistent quality and reliability.

Why Film Selection Matters in VFFS Packaging

The packaging film you choose directly impacts shelf life, product protection, and overall presentation. For dry food packaging, the film must maintain product freshness, resist moisture, and withstand the sealing process. Film strength and barrier properties are critical for keeping products safe from air, humidity, and contamination.

Common Film Options for Dry Foods

When packaging dry foods with VFFS machines, several types of films are commonly used:

Polypropylene (PP): Lightweight, moisture resistant, and ideal for snacks or baked goods.

Polyethylene (PE): Flexible and durable, often used as a sealing layer in laminated films.

Polyester (PET): Strong and heat resistant, often paired with other films for added protection.

Laminates: Multi-layer films that combine the strengths of different materials, offering superior barrier properties and shelf life.

Each of these films can be customized in thickness, clarity, and printability to match product and brand requirements.

Key Considerations When Choosing Materials

Selecting the right film for your dry food packaging involves more than choosing a single material. Brands must consider:

Barrier Properties: Protection against moisture, oxygen, and light.

Seal Strength: Ensures bags remain closed during shipping and handling.

Compatibility with VFFS Machines: Films must run efficiently to reduce downtime.

Sustainability Goals: Many brands now seek recyclable or eco-friendly films.

Product Visibility: Clear or windowed packaging can increase consumer appeal.

How Econo-Pak Helps You Succeed

At Econo-Pak, we understand that every product has unique packaging needs. Our experts work closely with clients to identify the best films and materials for dry foods, balancing performance, cost, and sustainability. With advanced VFFS machinery and a wide range of food packaging solutions, we deliver consistent results that keep products fresh, safe, and market ready.

We also offer procurement services, ensuring reliable sourcing of films and materials that meet your exact specifications. By partnering with Econo-Pak, you gain access to industry knowledge, certified quality standards, and packaging solutions that scale with your business.

The Right Partner for Your Packaging Needs

Choosing the right films for VFFS dry food packaging is a critical step in protecting product integrity and building consumer trust. With decades of experience, certifications like SQF Level 3, and a state-of-the-art facility, Econo-Pak is the partner that food brands trust to deliver results.

Ready to upgrade your dry food packaging? Contact Econo-Pak today and let us help you find the right films and materials for your products.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

What is the best granola and cereal co-packer?

Leave a CommentWhat is the best granola and cereal co-packer?

Granola and cereal are staple products in the dry food category, but bringing them to market successfully requires more than a great recipe. Your co-packer must ensure freshness, maintain product integrity, and offer packaging formats that appeal to both retail and club-store customers. Choosing the right granola and cereal co-packer is essential for scaling production without sacrificing quality.

Key considerations for granola and cereal co-packing

When selecting a co-packer for granola and cereal, consider the following:

Moisture control: Exposure to humidity can cause granola to clump and cereal to lose its crunch. A co-packer with controlled storage and packaging environments helps preserve freshness.

Portion consistency: Accurate weighing ensures that every bag or box meets your label claims and customer expectations.

Ingredient segregation: Many granola blends include allergens like nuts, which means you need a facility with robust allergen control and SQF Level 3 certification for food safety.

Scalability: Granola and cereal products often need to scale for retail and e-commerce channels, requiring equipment that handles both single-serve packs and club-size bag-in-box formats.

Packaging formats that work for granola and cereal

The right packaging not only protects your product but also influences its shelf appeal:

Bag-in-box: This classic format is ideal for large cereal runs, especially for retail and foodservice channels. It provides excellent product protection during shipping.

Stand-up pouches: Resealable pouches are popular for granola because they offer convenience and a premium look, making them perfect for natural and organic product lines.

Single-serve packs: Portion-controlled packs cater to on-the-go consumers and subscription box companies, making them an excellent choice for brand expansion into new markets.

Selecting a co-packer with multiple format capabilities ensures flexibility as your distribution channels grow.

How to choose the best granola and cereal co-packer

Your ideal co-packer should combine experience with innovation. Look for:

High-speed equipment: Large-volume runs require machinery capable of handling significant throughput without compromising accuracy.

Multiple packaging options: A facility that can handle pillow pouches, stand-up pouches, and bag-in-box formats gives you more market flexibility.

Advanced quality controls: SQF Level 3 certification demonstrates a commitment to food safety and process consistency.

Predictable pricing: Fixed-cost pricing models prevent budget surprises and support long-term financial planning.

Why Econo-Pak is the best choice for granola and cereal

Econo-Pak is an industry leader in co-packing dry food products, including granola and cereal. Our SQF Level 3 certified facility offers controlled environments to maintain product quality, and our 200+ packaging machines provide unmatched capacity for both small and large production runs.

We specialize in multiple packaging formats, including stand-up pouches, pillow pouches, and bag-in-box solutions for club and foodservice markets. With our fixed-cost pricing model, brands can scale confidently without worrying about fluctuating costs.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

Econo-Pak Through the Generations: A Wiebel Family History in Co-Packing Innovation

Leave a CommentEcono-Pak’s story spans more than a century, starting with inventive packaging ideas and growing into one of the leading high-volume contract food packaging companies in the United States. This journey has been shaped by entrepreneurial vision, family leadership, and a dedication to innovation in food packaging.

Early beginnings: Innovation in packaging (1902–1930s)

In 1902, Charles Cook—uncle of future Econo-Pak leader Paul Wiebel—became President of Tiffany’s. He later helped fund Paul’s creation of Econo-Pak. Another uncle, Peter Randolph, entered the packaging business between 1905 and 1920, selling wooden butter packages and folding cartons around the time of World War I.

The 1920s brought a pivotal meeting between Peter Randolph and Clarence Birdseye, the inventor of frozen food. During a lunch at Luchow’s in Manhattan, a spilled candle led Peter to experiment with wax-coated surfaces. That simple moment inspired the wax-coated box, the first frozen food package for Birdseye—an innovation that changed how frozen goods were shipped.

By 1934, Peter had brought Paul’s grandfather into the business, forging relationships with international brands that continue today.

Growth through the decades (1940s–1960s)

After serving as a Navy captain during WWII, Paul’s grandfather returned to expand into folding cartons and the newly developed corrugated boxes. In the late 1950s, Paul’s father, Jules Wiebel, launched Wiebel Associates with his wife, Dorothy. From their home and later an office in White Plains, NY, they sold packaging to major food producers.

The 1960s saw another advancement: Jules developed point-of-purchase (POP) corrugated displays, helping food brands stand out in stores.

From family basement to packaging plant (1968–1979)

Paul Wiebel joined the family business in 1968, working alongside his parents in their Parsippany, NJ home—Paul and his father in the basement and garage, his mother handling calls from the kitchen. In 1977, Wiebel Associates acquired Conocraft, a display manufacturer, and opened a 4,000 sq. ft. plant in East Hanover, NJ.

By 1979, Conocraft expanded into a 15,000 sq. ft. warehouse in Pine Brook, NJ, pioneering club store packs—bulk packaging for warehouse retailers.

Entering food packaging at scale (1980s–1990s)

In the early 1980s, Conocraft invested in a Doboy Flow Wrapper, making it possible to package single-serving products for major cookie brands. In 1981, the company rebranded as Econo-Pak and became FDA-approved by 1983.

The late ’80s and ’90s marked steady growth:

1986 – Moved into a 44,000 sq. ft. facility at 1 Wiebel Plaza.

1987 – Entered the flow wrapping business.

1990 – Added bundle wrapping and shrink wrapping capabilities.

1995 – Began producing pillow pouches with vertical form fill seal machinery.

Expanding capabilities and focus (2000–2014)

In 2000, Econo-Pak began producing variety packs with large flow wrappers and tray makers. Leadership transitioned in 2007 when PJ Wiebel became CEO. By 2009, the company had shifted its focus exclusively to food product packaging.

A major milestone came in 2014 with the move to a custom-designed Milford, PA facility created by architect Myron Goldfinger. That same year, Econo-Pak earned the SQF Level 3 certification, the highest standard in food safety.

Modernizing operations (2015–2024)

From 2015 onward, Econo-Pak embraced technology to improve efficiency and product quality:

2015 – Transitioned to servo equipment.

2016 – Purchased the Milford facility and added energy-efficient, temperature-controlled ductwork.

2022 – Updated the company logo to reflect a modern brand identity.

2024 – Invested in the first robotic production line, automating physically demanding tasks.

Looking ahead

From a spilled candle in a New York restaurant to a fully automated, high-volume production floor, Econo-Pak’s history reflects a deep commitment to packaging innovation. With over a century of expertise, the company continues to evolve, embracing technology and sustainable practices to meet the future of food packaging.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.

Scaling Production: Transitioning from Small to Large Co-Packers

Leave a CommentAs your food brand grows, the demand for higher production volumes, increased efficiency, and expanded capabilities becomes inevitable. For many small and medium-sized food businesses, co-packers play an essential role in scaling operations, but not all co-packers are equipped to handle rapid growth.

When production requirements outgrow the capabilities of a small co-packer, transitioning to a large co-packer can offer the tools, technology, and resources necessary to sustain and accelerate growth.

Key Differences Between Small and Large Co-Packers

Choosing between a small co-packer and a large high-volume co-packer is a pivotal step in scaling your food brand. As your business grows, the right co-packing partner can help you meet rising demand, streamline production, and access major retail markets.

Understanding the differences between small co-packers and large contract food packaging companies will help you determine when it’s time to upgrade to a partner that offers the capacity, technology, and services needed to support your long-term growth.

Small co-packers

Lower volume capacity: Ideal for emerging brands and small batch production but limited in scaling to meet larger retail demand.

Hands-on approach: Often able to provide manual packaging services, making them a good fit for startups and low-volume niche products.

Basic service offerings: May only offer specific types of filling, cartoning, and other packaging services.

Simpler equipment: Use smaller-scale machinery suitable for low-volume runs but less suited for large-scale automation.

Large high-volume co-packers

High production capacity: Equipped to handle large order volumes for big-box retailers and national grocery chains.

Expanded services: Offer additional capabilities such as market diversification, contract manufacturing services such as blending, and more.

Advanced technology: Invest in automation and sophisticated machinery to increase efficiency and ensure consistent product quality.

Cost efficiency at scale: Require higher minimum commitments but deliver better economies of scale with lower per-unit costs as demand grows.

Signs It’s Time to Transition to a Large Co-Packer

Transitioning to a large co-packer isn’t a decision you make overnight. There are several telltale signs that it’s time to make the switch:

1. Increased demand:

When your existing co-packer struggles to meet the growing demand for your product, it may be time to move on. If lead times are increasing and orders are being delayed, it’s a clear sign that you’ve outgrown your current arrangement.

2. Operational efficiency:

If your co-packer can’t keep up with the speed and precision your business requires, a large co-packer may offer faster turnaround times. Larger facilities typically have optimized processes and more advanced technology to support higher production speeds while maintaining product consistency.

3. Compliance and certifications:

Large co-packers often maintain a wide range of food safety certifications, such as SQF (Safe Quality Food), organic and kosher certifications, and more. As you expand into larger markets, having a partner with the necessary certifications can help ensure you meet the regulatory requirements of larger retailers.

4. Entering new markets:

If you’re looking to sell your product in major retailers like Costco, Walmart, or national grocery chains, large co-packers are often better suited for this type of scaling. They have experience in meeting the requirements of these retailers, including the ability to handle bulk shipments and ensure that products meet stringent quality standards.

Evaluating Large Co-Packers for Your Brand

Choosing the right large co-packer is a critical decision that can directly impact your brand’s success. Start by researching their reputation and track record, focusing on whether they’ve worked with products that share your production, storage, or compliance requirements. Ask for references or testimonials to validate their industry standing.

Next, consider their capacity for growth. Even if they can handle your current production levels, you need assurance they can scale with you as demand increases. Be upfront about your growth goals and confirm they have the space, equipment, and resources to match your trajectory.

Pricing transparency is another key factor. Some co-packers offer fixed-cost pricing to simplify budgeting and avoid surprises, while others rely on variable cost models that may offer flexibility but risk unpredictable expenses.

Technology should also play a major role in your evaluation. Co-packers with automation, custom packaging solutions, and advanced quality control systems can maintain consistency and efficiency as your volumes grow.

Finally, prioritize customer support and communication. Large operations can be complex, so it’s essential to work with a co-packer that offers clear communication protocols, dedicated account managers, and project management support to keep your production on track and your brand a priority.

Steps to Smoothly Transition to a Large Co-Packer

Transitioning to a large co-packer can be a complex process, but with the right steps in place, you can ensure it goes smoothly:

1. Plan the transition early:

Start preparing for the switch long before it becomes absolutely necessary. A last-minute transition can lead to production delays, miscommunication, and even supply chain disruptions. Build in plenty of time for onboarding the new co-packer and testing their processes.

2. Audit your current operations:

Before making the switch, take the time to document your current production processes, volumes, and quality standards. Share this detailed information with your new co-packer so they can understand your expectations and any unique requirements of your product.

3. Build strong partnerships:

Treat your new co-packer as a partner, not just a service provider. Establish clear expectations, be transparent about your growth goals, and make sure both sides are aligned on timelines and performance metrics. A strong working relationship is key to long-term success.

4. Monitor the first production runs:

During the first few production cycles, closely monitor product quality, production timelines, and communication. If any issues arise, address them immediately with your co-packer to ensure that they can be resolved before full-scale production ramps up.

Position Your Brand for Continued Success

Scaling your production from a small to a large co-packer is a significant step that can position your brand for long-term success. As demand for your product grows, partnering with a larger co-packer can provide the capacity, technology, and support needed to meet customer expectations and enter new markets. However, ensuring that you choose the right co-packer and manage the transition carefully is essential for a smooth process.

By evaluating your options and planning thoroughly, you can make the transition confidently and set your brand up for continued growth.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.