The food industry is evolving at record speed, and contract food packaging has become essential for brands looking to stay ahead. With shifting consumer preferences, rising sustainability demands, and new retail opportunities, packaging isn’t just about protecting a product—it’s a strategic tool that can drive growth and increase market share.

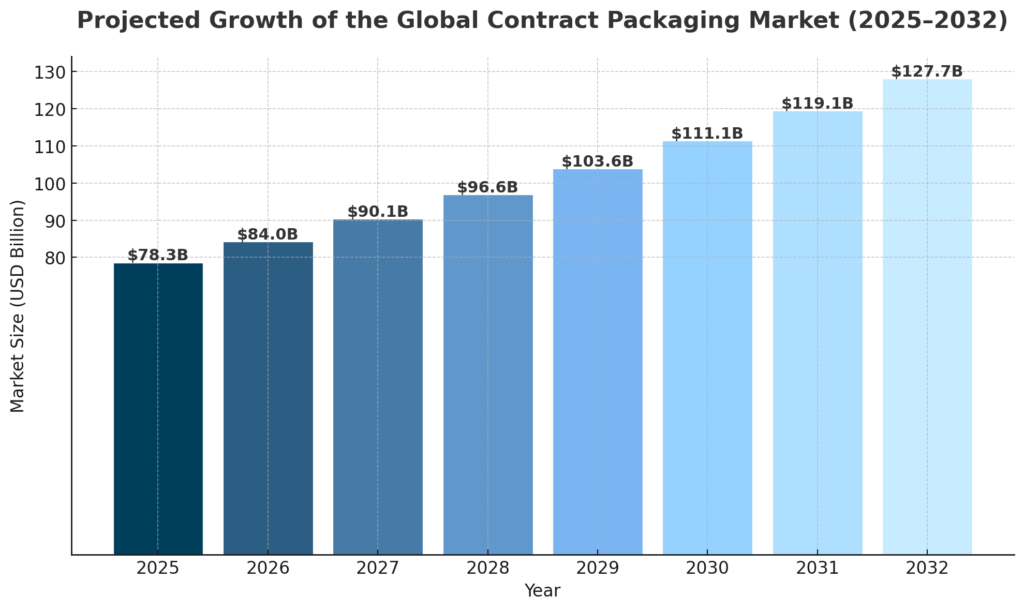

Consider this: the global contract packaging market is projected to reach $117 billion by 2030, growing at a 7% CAGR, as more companies lean on experts to streamline operations and reduce costs.

For brands searching for “food co packer near me” or exploring private label packaging to break into new markets, understanding the latest innovations can give you a competitive edge.

In this article, we’ll break down how to choose the right partner, key differences between co-packing and co-manufacturing, and what’s trending in packaging technology—all with insights designed for packaging managers, startup CEOs, and contract manufacturing leaders.

What is contract food packaging?

Contract food packaging is the behind-the-scenes hero of the supply chain, allowing brands to outsource their packaging processes so they can focus on scaling, marketing, and product development.

By working with a contract packager, companies benefit from:

- Flexible production runs

- Reduced capital investment in packaging automation and machinery

- Expertise in regulatory compliance

- Faster speed to market

And with over 50% of CPG companies now outsourcing part of their packaging operations, it’s clear that scalability and cost efficiency are driving adoption across the industry.

Co-packing vs. co-manufacturing: What’s the difference?

For anyone looking into “co packers near me,” it’s important to understand the distinction:

While co-packing is ideal if you have a finished product that needs packaging, co-manufacturing is perfect if you need help producing the product itself from raw ingredients to final packaging.

Why private label packaging is a growth strategy

Private label packaging is booming. Private label food sales hit $271 billion in 2024, up 14% from 2023, in the U.S. alone, driven by consumers seeking quality at a better price. For brands, private label packaging is more than just slapping a name on a product—it’s about crafting a unique identity and standing out on crowded shelves.

Benefits of private label packaging include:

- Customizable designs that align with brand values

- Sustainable material options to appeal to eco-conscious buyers

- Faster entry into new retail spaces, like club stores and convenience chains

The role of automation and robotics in contract packaging

Automation is no longer a luxury; it’s the standard to achieve high-volume production with maximum efficiency. In contract food packaging, automation delivers:

- Precision and consistency in every run

- Real-time quality control

- Scalability for high-volume demand

As product demand fluctuates, automated lines help businesses stay nimble without sacrificing quality.

Why location matters when searching for “food co packer near me”

Looking for “co packers near me” isn’t just about convenience—it’s a strategic move. A local food co packer helps reduce freight costs and speed up delivery timelines, which is crucial when 58% of consumers have paid more for faster delivery, with most having paid extra for next-day (69%) and same-day delivery (61%).

Regional packers also understand local regulations, climate considerations, and retailer preferences, making them valuable partners for expanding into specific markets.

Turnkey contract packaging: One partner, total support

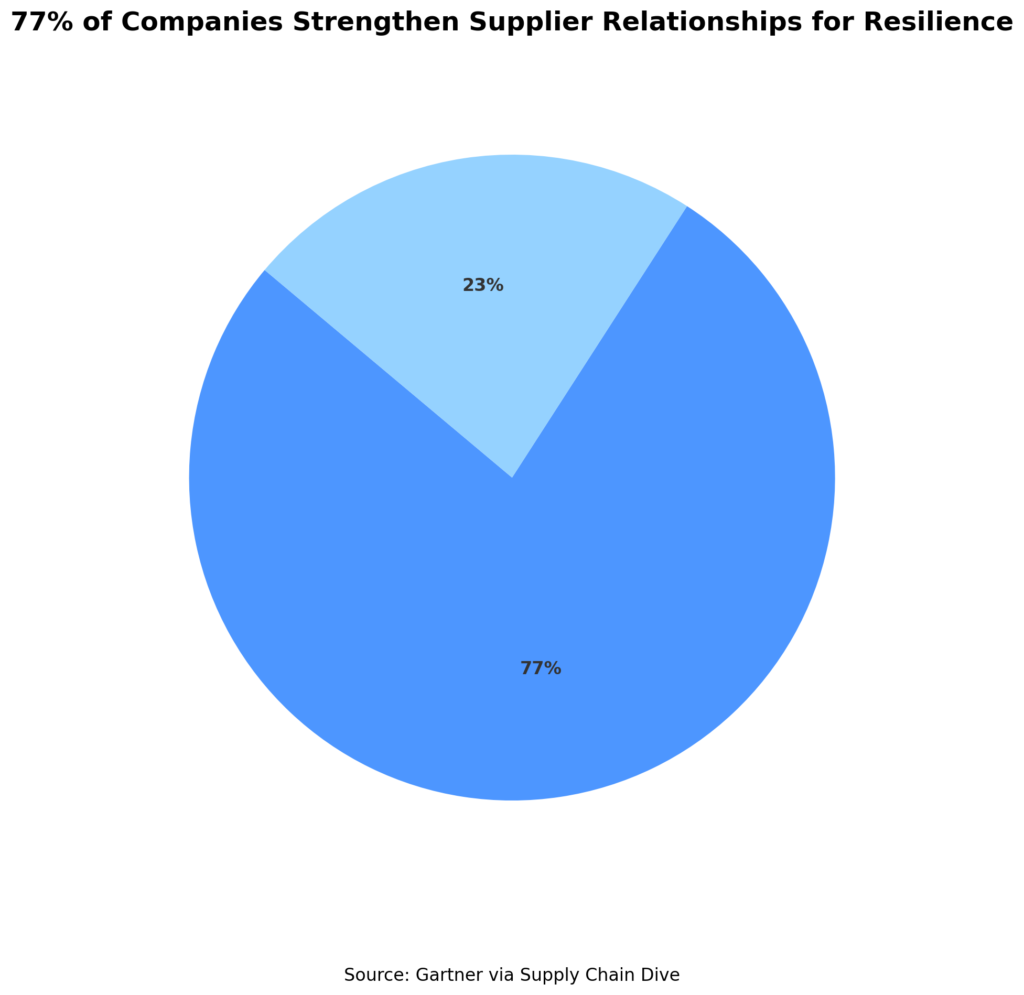

Brands are increasingly turning to turnkey contract food packaging partners that handle everything from sourcing materials to final distribution. In fact, 77% of companies are investing in deeper and more collaborative supplier relationships to enhance resilience and agility.

Turnkey services offer:

- A dedicated team to your project

- Material sourcing

- Blending, seasoning, and grinding services

- Packaging, warehousing, and shipping

The result? Simpler project management and faster go-to-market timelines.

The future of contract packaging

Sustainability, technology, and flexibility are driving the next wave of innovations in contract packaging:

🔹 Smart packaging with QR codes for traceability

🔹 Biodegradable films to meet eco goals (with 60% of consumers preferring recyclable packaging)

🔹 Digital printing for hyper-personalized product runs

By staying ahead of these trends and partnering with experienced co-packers, brands can future-proof their operations and capitalize on shifting market demands.

Why choose Econo-Pak as your private label co-packer?

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.