Importance of Dielines in Quoting Co-Packing Projects

Precision is everything in co-packing. Every element of a packaging project—materials, dimensions, sealing, labeling—affects production efficiency and costs.

One of the most critical factors in providing an accurate co-packing quote is the dieline. Without it, pricing and feasibility assessments become challenging, often leading to delays, cost discrepancies, or unexpected production issues.

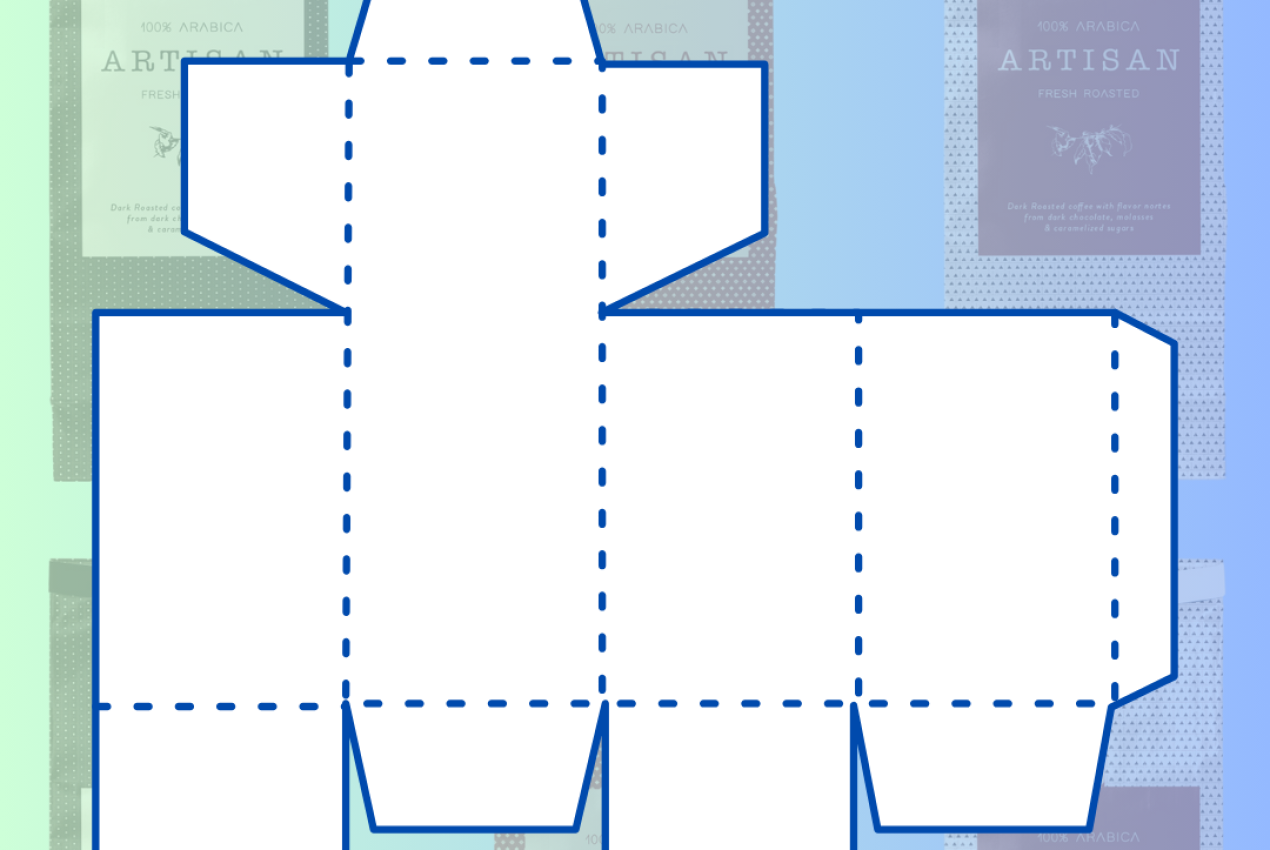

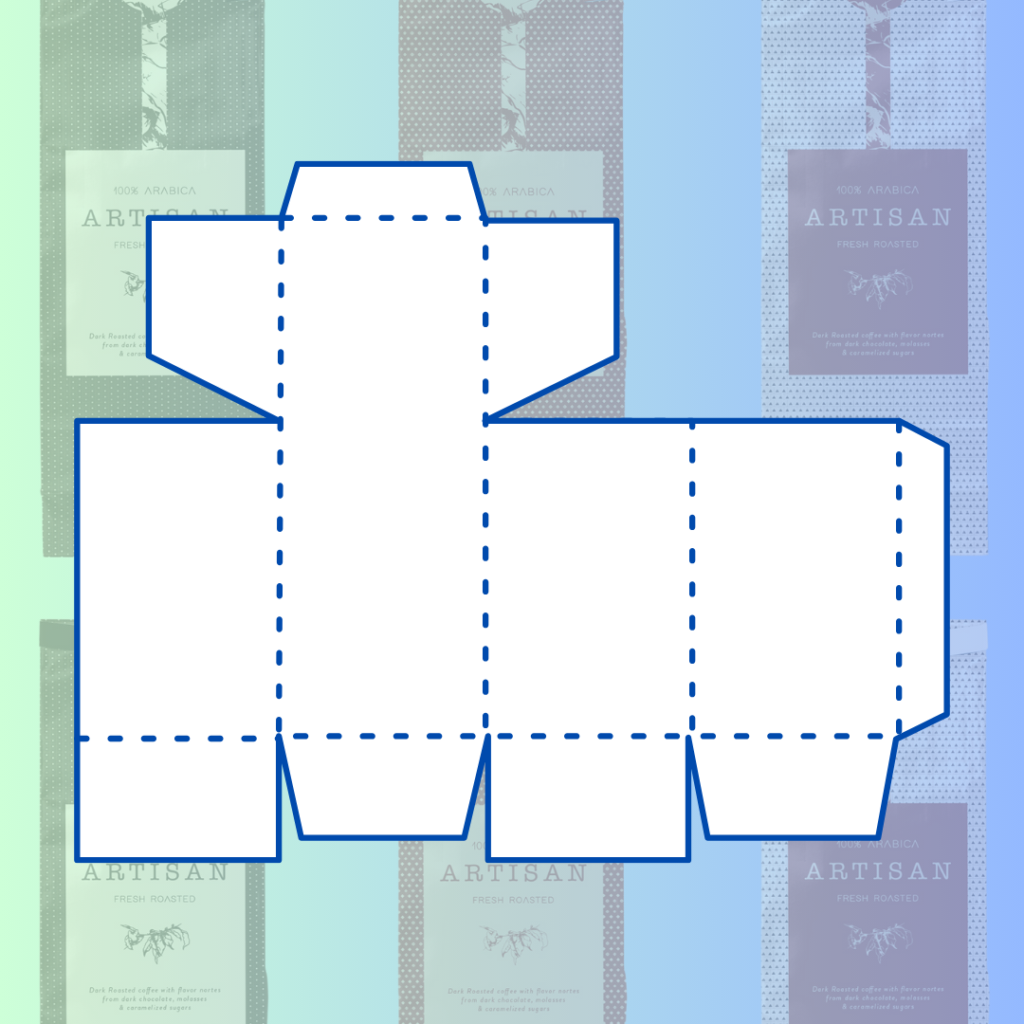

What is a dieline?

A dieline is a technical blueprint that outlines the shape, size, and folding lines of a package. It acts as a guide for both structural design and printing, ensuring that all components fit together correctly. Dielines in packaging help define key specifications such as:

Cut lines – Indicating where the material will be cut.

Fold lines – Showing how the package will be assembled.

Bleed areas – Ensuring designs extend beyond the trim line to prevent unprinted edges.

Safe zones – Marking areas where important graphics or text should be placed to avoid being cut off.

Why dielines in packaging matter in co-packing quotes

Providing a dieline upfront allows co-packers to generate accurate and reliable co-packing quotes by:

1. Determining material requirements

Without a dieline, it’s difficult to estimate the exact amount of packaging material needed. A properly defined dieline ensures that material waste is minimized and the most cost-effective options are used.

2. Assessing machine compatibility

Co-packers need to determine whether existing machinery can handle the package dimensions and structure. Certain package designs may require custom tooling or specialized packaging equipment, impacting the overall project cost.

3. Calculating labor and production time

The complexity of a dieline affects how a package is assembled. A simple tuck-top box requires far less time and labor than a multi-panel, intricate structure. Having a dieline helps estimate labor requirements and streamline production timelines.

4. Avoiding delays and miscommunications

Without a dieline, assumptions must be made about packaging dimensions and layout, which can lead to costly mistakes or production delays. Clear, precise dielines eliminate guesswork and ensure all stakeholders are aligned from the start.

What happens if a dieline isn’t provided?

If a dieline isn’t available, co-packers must rely on estimations, often leading to:

Overestimated or underestimated costs – Affecting project budgets and profitability.

Production inefficiencies – Requiring additional time for adjustments or redesigns.

Packaging errors – Leading to improper fits, structural failures, or misaligned prints.

How to ensure a smooth quoting process

For brands looking to receive an accurate co-packing quote, providing a dieline upfront is key. Here are some best practices:

Work with your designer or packaging supplier to create a production-ready dieline.

Ensure dielines are in vector formats (such as AI, PDF, or EPS) for precision and scalability.

Include all technical details like dimensions, material specifications, and finishing requirements.

Communicate any modifications early in the process to prevent rework or cost increases.

Send us your project today

Dielines in packaging are more than just templates—they are essential tools for accurate co-packing quotes, efficient production, and successful co-packing projects. By providing clear and detailed dielines upfront, brands can streamline the quoting process, avoid unexpected costs, and ensure their packaging meets both functional and aesthetic expectations.

For brands looking to scale with contract packaging, having a dieline ready is one of the first steps toward a seamless and cost-effective partnership.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.