In recent years, the food packaging industry has seen a significant improvement in technology, with one of the most revolutionary advancements being the use of robots.

Robotic systems offer many advantages over manual processes and are continuing to transform the food packaging industry now and into the future.

The Current Landscape of Food Packaging Robots

Food packaging robots come in numerous types, each specializing in different packaging tasks. Common types include:

- Pick and place robots. These robots perform well in tasks such as arranging, sorting, and placing food products into packaging containers with precision.

- Collaborative robots. Collaborative robots work alongside human workers and are commonly used in packaging applications requiring a high degree of flexibility and adaptability.

- Retort machines. These automated machines are specifically designed to preserve food products and ensure optimal quality, safety, and shelf life.

- Fully automated packaging lines. Automated packaging lines utilize a combination of robotics, conveyors, and other equipment to streamline the entire food packaging process.

Benefits of Food Packaging Robots

Food packaging robots offer several advantages over traditional manual processes. These advantages include:

- Better efficiency and productivity. Food packaging robots are capable of working continuously without breaks for enhanced productivity. They greatly reduce packaging times, resulting in significant cost savings and faster delivery to consumers.

- Enhanced product quality and consistency. Robots can package food products with minimal risk for error. This leads to enhanced packaging quality, precision, and consistency.

- Cost savings and reduced labor dependency. Although the initial investment in advanced robotics technology may be high, the long-term cost savings are often significant due to lower labor costs and enhanced efficiency. Robots can also be easily reprogrammed or reconfigured to handle different packaging tasks without the need for additional labor.

- Minimization of rote task-related injuries. Food packaging robots take on tasks that require repetitive motions. These types of movements can lead to overuse injuries in humans, so workers can enjoy a more comfortable job position while the robots do the menial labor.

- Improved food safety and hygiene. Robotic packaging systems can operate in sterile environments, helping businesses reduce the risk of contamination while remaining compliant with FDA food packaging regulations. They are also capable of handling delicate food products without the risk of damage or contamination.

- Reduced human error and packaging waste. The automated nature of food packaging robots minimizes the risk of human error, resulting in reduced waste and improved product quality.

Food Packaging Robots Applications

Robotics are capable of carrying out numerous tasks related to the food packaging process. Common applications include:

- Pick and place of randomly oriented food items

- Raw food packaging

- Depanning

- Denesting

- Boxing

- Palletizing

- Warehousing tasks

Technological Components of Food Packaging Robots

The efficacy of food packaging robots depends on various cutting-edge technological components. Today’s advanced robotics systems typically include the following:

- Sensors that allow robots to perceive their environment

- Machine vision systems for quality control purposes

- Sophisticated software and programming tools

In addition to the abovementioned elements, food packaging robots are often integrated with other packaging machinery and systems to create a seamless and efficient packaging process.

Challenges of Food Packaging Robots

Despite their numerous benefits, food packaging robots can come with several challenges, including:

- Higher upfront costs, which may deter smaller businesses

- Require a certain level of maintenance and technical expertise to remain operational

- Can be difficult to ensure compliance with food safety regulations

- Concerns about potential job displacement as automation becomes more common in the industry

If you are considering outsourcing your food packaging due to the limitations discussed above, contact us today and we’ll give you a fixed-price quote for your project.

The Future Prospects of Food Packaging Robots

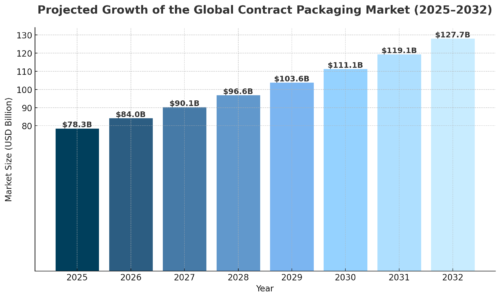

The future of food packaging will undoubtedly see increased implementation of robotics and other automated systems. As we dive deeper into Industry 4.0, the food packaging industry will continue to use robotics to enhance packaging efficiency and decrease costs.

On top of the previously mentioned benefits, robots are also expected to help with sustainability initiatives by reducing waste and creating more eco-friendly food packaging materials. Artificial intelligence and machine learning will further improve the capabilities of food packaging robots by enabling them to easily adapt to changing demands and product requirements.

Meet the Future of Food Packaging With Your Own Robotic Solutions

Robots not only improve the speed and quality of food packaging operations but also help to reduce waste and labor costs. At Econo-Pak, we are dedicated to continuously advancing our contract food packaging services through the use of cutting-edge equipment and robotic automation.

For more information about our contract food packaging capabilities and the equipment we use, request a quote today.

Let's start scaling.

Is your demand outpacing your ability to package your own product? Then consider outsourcing with Econo-Pak.

With over 40 years of experience working with both small brands and Fortune 500 companies, we are capable of handling your specific dry food product.

Get in touch with our team for a fixed-price quote for your project.