With increasing demand for spices, protein powders, and even chemical additives, market demand for dry and powdered products is growing daily. Using the most cutting-edge auger filling technology, the specialty packaging team at Econo-Pak can manage a huge range of food-grade powders, nuts, salts, raw-food ingredients, and so much more.

With increasing demand for spices, protein powders, and even chemical additives, market demand for dry and powdered products is growing daily. Using the most cutting-edge auger filling technology, the specialty packaging team at Econo-Pak can manage a huge range of food-grade powders, nuts, salts, raw-food ingredients, and so much more.

In addition to auger filling, we support all contract packaging projects with wrapping, display, labeling, and full-service kitting capabilities, serving customers’ needs throughout every step of the packaging process.

What is Auger Filling?

Auger powder and dry filling machines operate with fast, efficient precision; these tools minimize product waste while maximizing fill consistency. Equipped with electronic volume sensors and long-lasting, high-volume capabilities, auger fillers are excellent tools for managing loose material packaging in a variety of formats, including customizable fills in the following packages:

- Pouches, pillow pouches, and individual sachets both large and small, for optimal versatility

- Stand-up pouches (SUPs) with on-trend, modern shelf display options

- Classic bottles, boxes, and jars

- Shipping-optimized rigid and flexible containers

- Club-format and multipack containers for unique applications

- Containers to be further processed in film and shrink wrapping

The most popular auger-filled packaging, by far, is the pouch style; gusseted, vacuum-sealed, flexible, zippered, portion-sized, and four-sided pouches are all highly reliable dry goods solutions.

Capabilities: Powdered and Dry Materials

Whether non-free-flowing, semi-free-flowing, or completely free-flowing, auger fillers seamlessly manage dry goods handling processes for foods, beverages, cosmetics, pharmaceuticals, and more.

Some of the most common materials we process include:

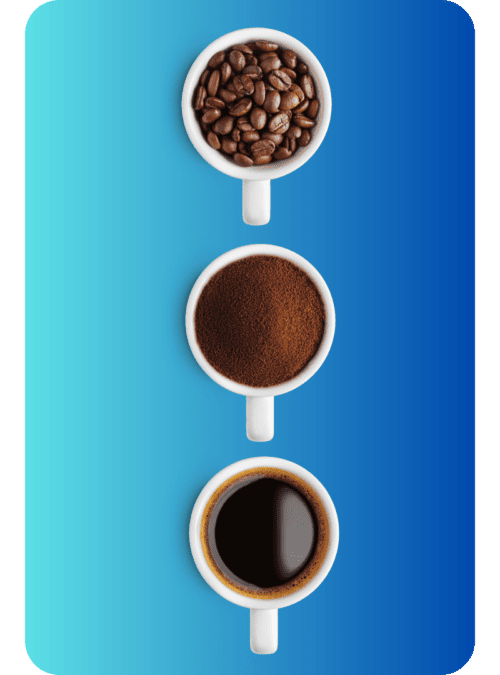

- Instant coffee, coffee beans, powdered milk, and beverage mixes

- Protein powders and nutritional supplements

- Candies, popcorns, and snack foods

- Pre-packaging for spice blends, grain mixes, and seasonings

- Baking powders, flour, and pastry mixes

- Processed sugar, brown sugar, and table salt

- Whole nuts, granola, and trail mix

While auger filling is highly versatile, it can be damaging to delicate materials. For example, fresh fruit, raw vegetables, and delicate snacks and cereals can be crushed at an auger filler’s high speed and volume. Reach out to a packaging expert to find a superior solution for fragile goods, and weigh all options carefully.

Auger Filling Services from Econo-Pak

The Econo-Pak team is proud to serve packaging needs of all types of sizes, for a huge range of applications and industries. We make use of the highest-quality, most innovative modern packaging solutions available, and are proud to serve diverse packaging needs. No matter how complex a project, our team will have a solution at the ready.

To learn more about our auger fillers and dry goods solutions, reach out to the team today; an expert is on hand to discuss options for your unique contract food packaging needs.